IEK ERM

IEK ERM

A service for analyzing and visualizing data of technological processes and energy resources, based on machine learning technologies.

This service provides asset optimization and integration with enterprise management automation systems (ERP) and real-time data acquisition and processing systems (SCADA).

-

Comprehensive

optimization -

Internal and external

expertise -

Data-driven

solutions -

Reliable solutions

Sources of production losses

The product's cost structure is heavily impacted by systemic inefficiencies, including material waste that causes equipment wear and downtime, high energy expenses from poor consumption patterns and a lack of monitoring, direct losses from defects, and an inability to make informed decisions without proper process data analysis.

-

Resource waste and unplanned downtime

-

Equipment breakdowns due to non-compliant specifications or raw material overconsumption

-

Direct costs of production waste

-

Inability to analyze production and energy data due to the lack of a dedicated system

-

Production costs account for a large share of the total product cost

-

Elevated energy expenses caused by inefficient consumption patterns, uneven equipment utilization, and high utility rates

Foresight and Efficiency

-

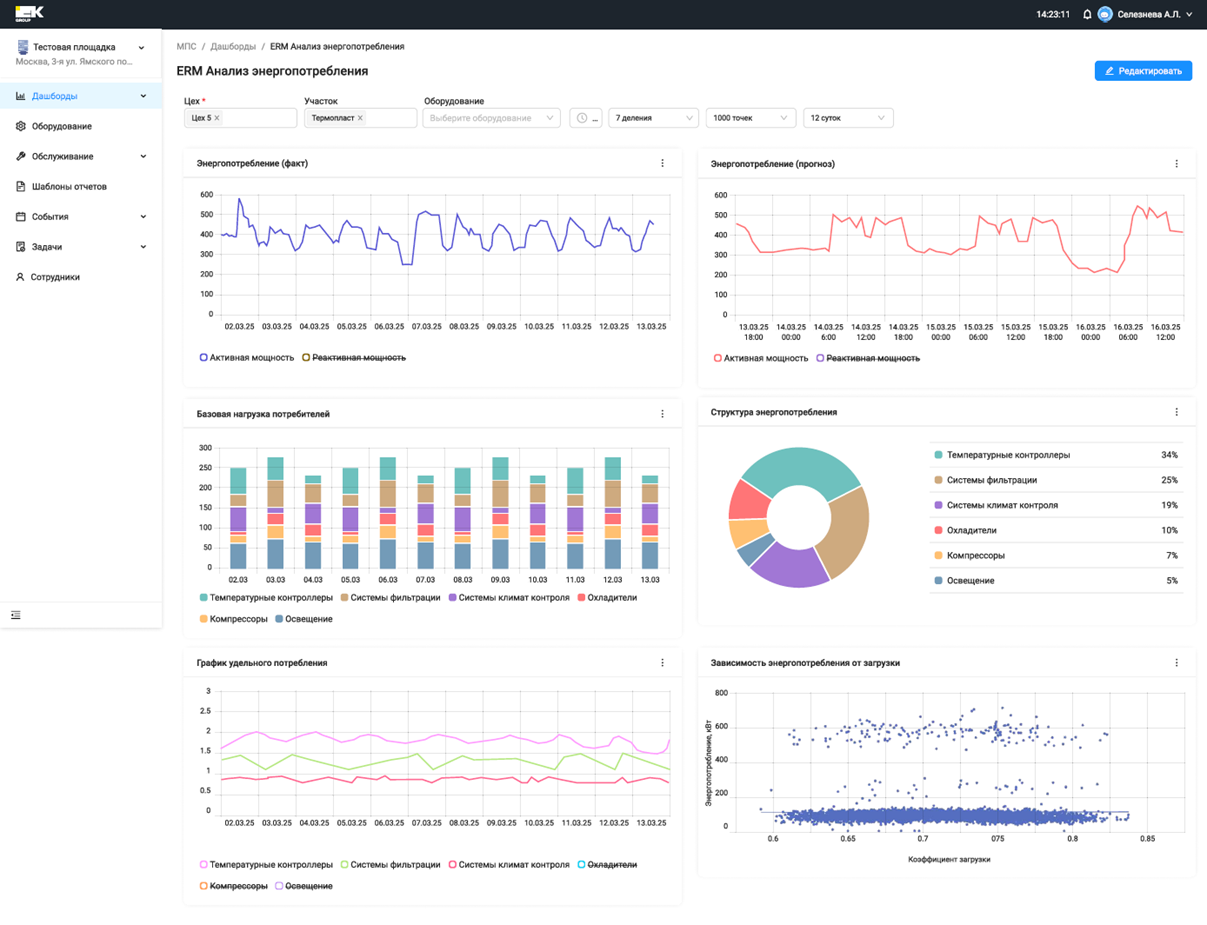

Energy Management and Forecasting

-

ML‑load forecasting

Machine learning algorithms analyze historical data and weather conditions to accurately predict energy consumption and optimize work schedules (reducing costs by 15–25%)

-

Energy consumption forecasting subsystem

Electricity consumption forecasts for participation in the Wholesale Energy Market and assessment of overpayments based on AMI meter readings

-

ML‑load forecasting

-

Process Modeling and Optimization

-

AI-based process modeling

Modeling of continuous and discrete production processes using Artificial Intelligence helps identify optimization potential and develop algorithms to achieve target indicators

-

Integration with APS

Using real production data in conjunction with the existing Automated Production Control System helps to adaptively respond to changes, incorporate real data into planning, and build an inventory management system

-

AI-based process modeling

-

Production Quality Assurance

-

Computer vision

The computer vision system helps improve product quality and respond faster to quality degradation. Automatic defect detection and production process optimization enable immediate sending of defective products for rework

-

Computer vision

-

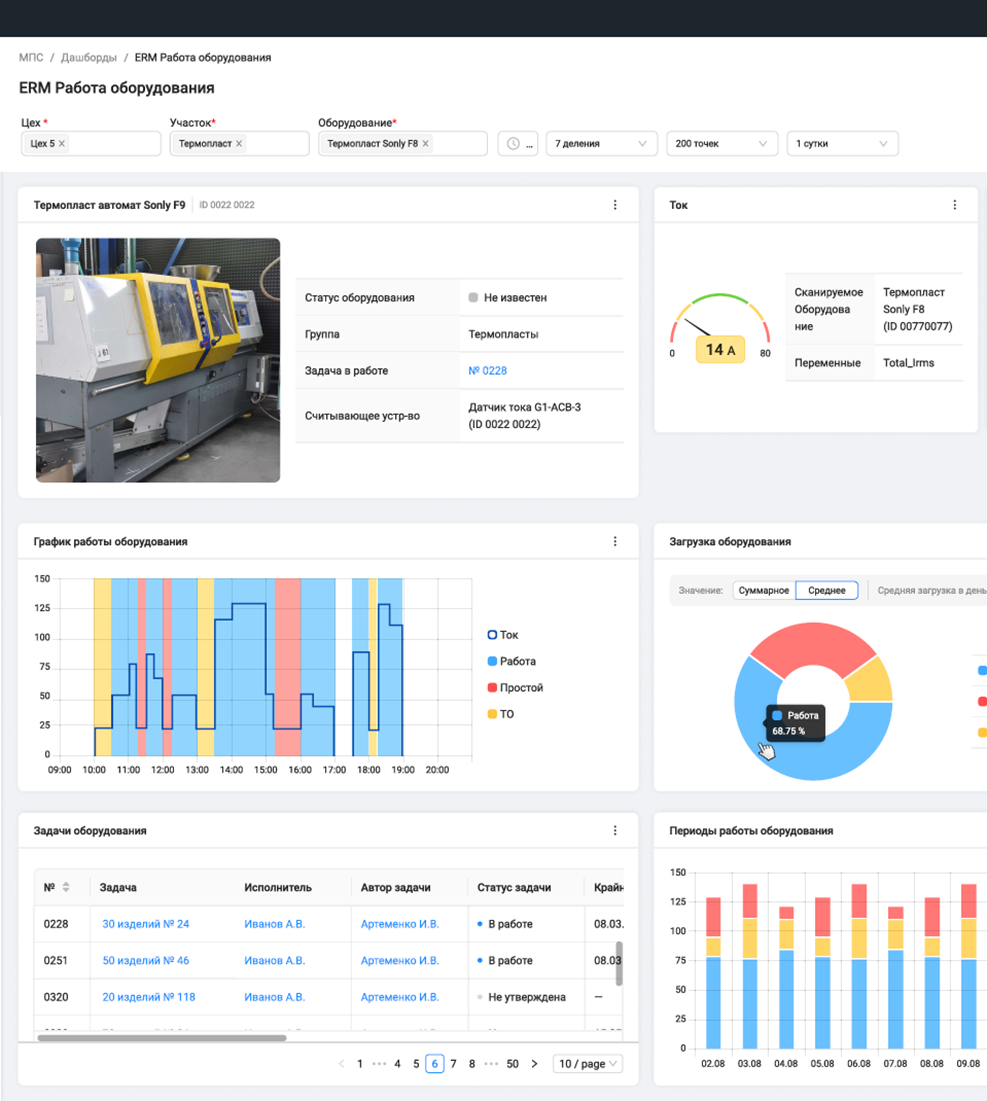

Predictive Analytics

-

IoT + ML models

IoT sensors combined with ML models predict equipment component wear (e.g., pump bearings), reducing downtime by an average of 30–40%

-

IoT + ML models

Value for Key Roles

Ensuring uninterrupted equipment operation through early warning of deviations. A set of ready-made reporting forms with customization options helps analyze peak loads and efficiently redistribute energy consumption.

Assistance in preventing accidents through predictive analytics to reduce unplanned downtime. Real-time energy consumption data allows for prompt adjustment of equipment operation parameters, enhancing the stability and reliability of the production process.

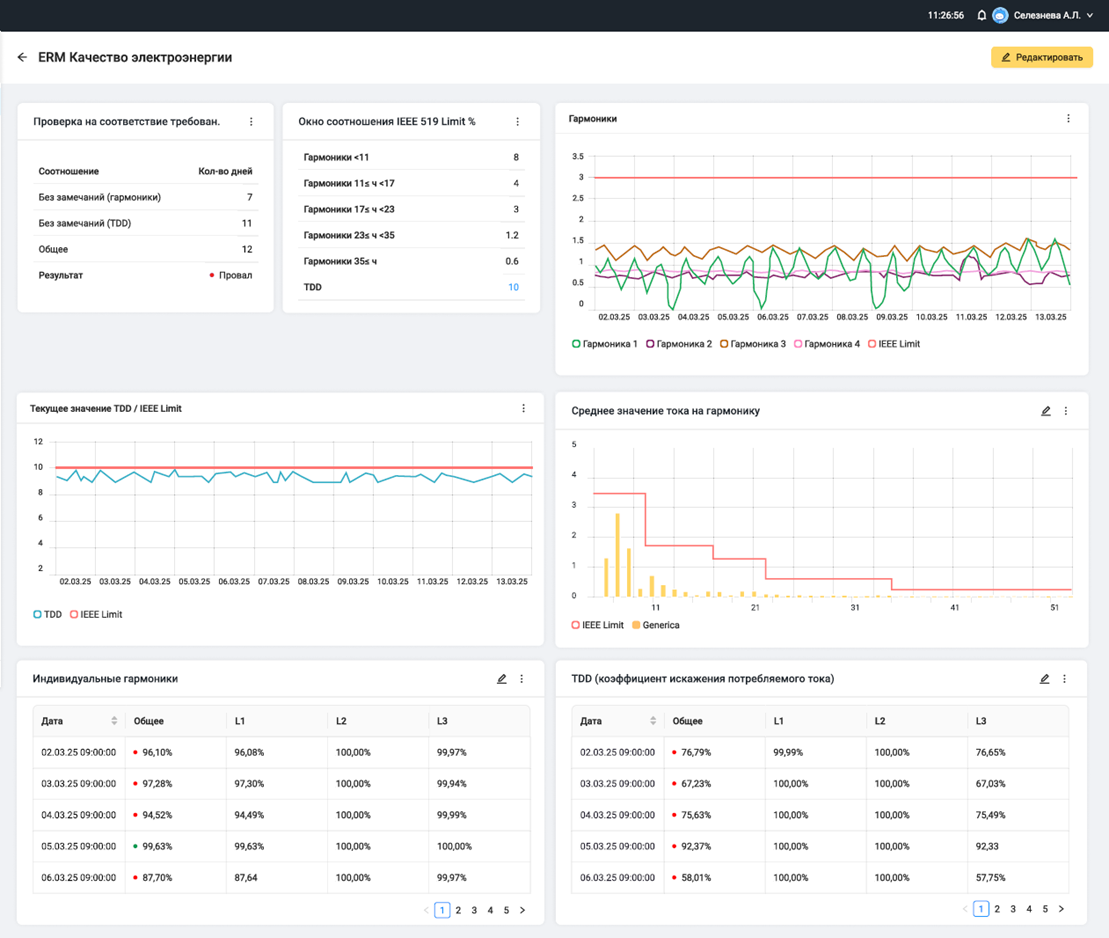

Detailed tracking of energy consumption across workshops, sections, and down to individual equipment. This enables pinpointing energy waste ("leaks") and leverages predictive analytics for optimized planning.

A single platform resolves disputes between production and energy teams by using data on unplanned downtime to synchronize line scheduling.

Achieving compliance with international standards (ISO 50001) and ESG criteria to enhance customer and partner loyalty, as well as meeting the requirements of Federal Law No. 261 «On Energy Saving» and avoiding penalties from regulatory authorities.

Let's work together

for integration into our standardized solutions portfolio