System purpose

The automation system being implemented across the enterprises of the Moskabelmet group of companies is designed to address tasks related to monitoring and managing key production processes. Its primary role is to increase productivity, enhance product quality control, and reduce the consumption of fuel and energy resources. The system is intended to ensure transparency across all stages of the production cycle, from tracking equipment downtime to monitoring product manufacturing parameters.

The primary objective of implementing the new automation system is to increase shift-based production output, minimize overconsumption of energy resources, reduce the number of manufacturing defects, and optimize equipment utilization. An important additional aspect is analyzing employee performance efficiency and identifying the root causes of deviations from planned targets.

The implementation of the new system also included a number of other goals:

Solution

Moskabelmet deployed MasterSCADA to optimize production, managing over 100,000 data tags. The system integrates PulseHub controllers and OWEN MV110 meters to track equipment downtime and productivity.

Using C# blocks, operators input downtime reasons, enabling transparency and quick resolution of inefficiencies. The system correlates equipment performance with workforce productivity, identifies bottlenecks, and reveals hidden production reserves through utilization rate analysis.

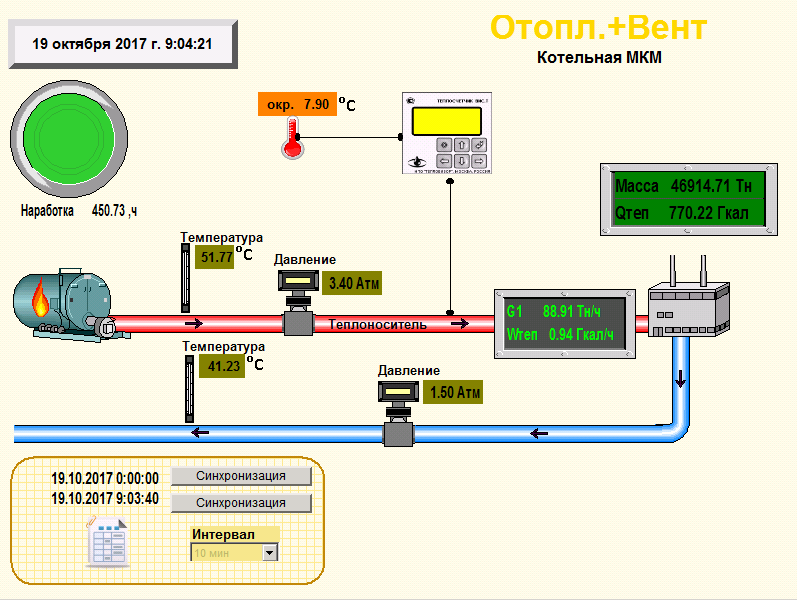

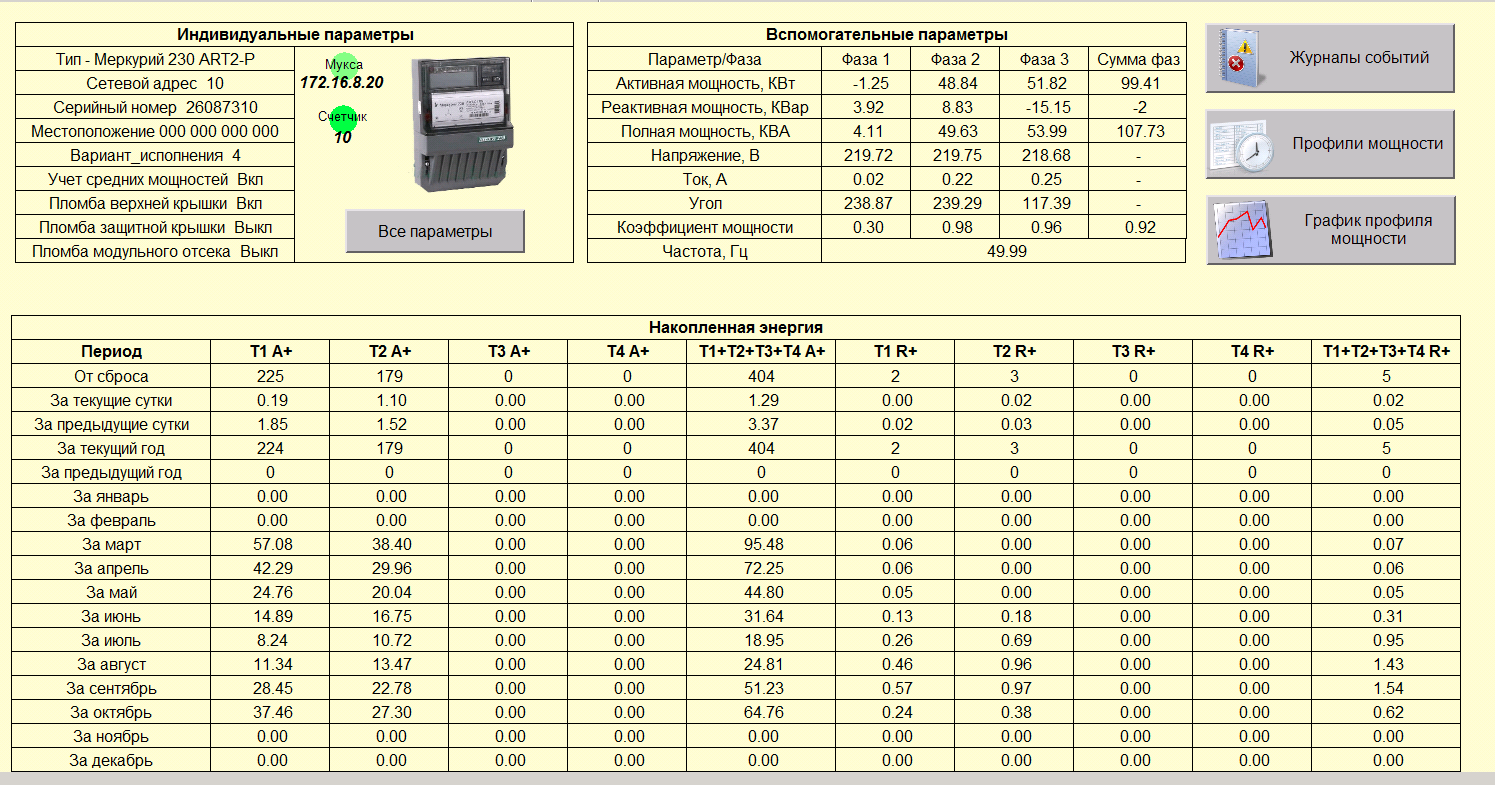

MasterSCADA optimized energy resource management by integrating Mercury and VIST meters with OPC servers, reducing idle time and energy costs. A faulty hard drive issue was detected, eliminating unnecessary equipment operation.

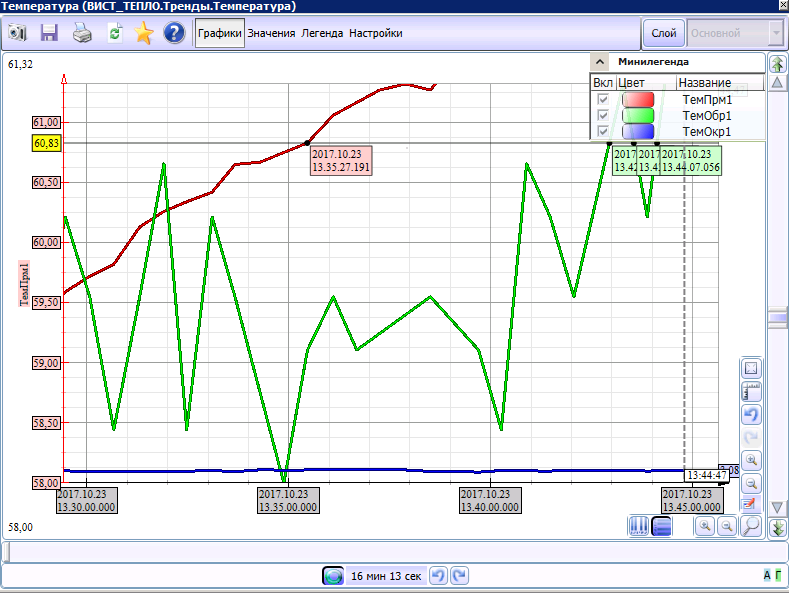

Additional controllers monitor critical parameters (temperature, speed) to prevent defects. An optical recognition system ensures real-time quality control by monitoring geometric parameters, improving overall product quality.

System functions

The MasterSCADA software installed in automated workplaces provides the following functions:

Result

The primary outcome of the automation project implementation within the Moskabelmet group of companies is the ability to create transparency in production processes at all stages of product manufacturing. The acquired data enables the identification of bottlenecks in the work of both equipment and operators. The greatest effect is achieved when the monitoring system covers not individual production segments but the entire spectrum of technological processes. A comprehensive approach reveals the interdependencies between processes, which, in turn, allows for making highly effective management decisions to normalize production processes and eliminate losses. The automation system comprises 165,000 variables, 1,500 physical I/O channels, 240 trends, and 150 reports. Subsequent operation and development of the system will enable the identification of reasons for production output variations between shifts, instances of deviations from set technological process parameters and their root causes, hidden and unused reserves, and opportunities to optimize production capacity, freeing it up for product manufacturing.