System purpose

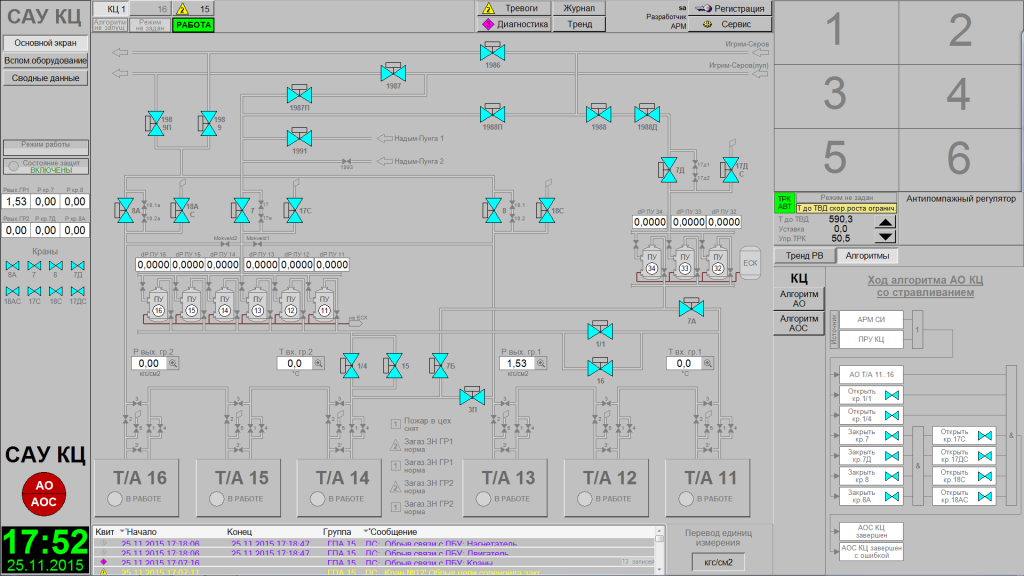

The objective of the new system implementation project was to develop an efficient solution for the automatic control and management of a compressor shop housing six gas pumping units (GPUs). The core challenge was the integration of diverse process components into a unified system that would ensure reliability, flexibility, and compliance with Gazprom's Corporate Standards (STO). The system was required to provide not only process monitoring and control, but also advanced equipment diagnostics and protection capabilities.

The implementation of the new system also included a number of other goals:

Solution

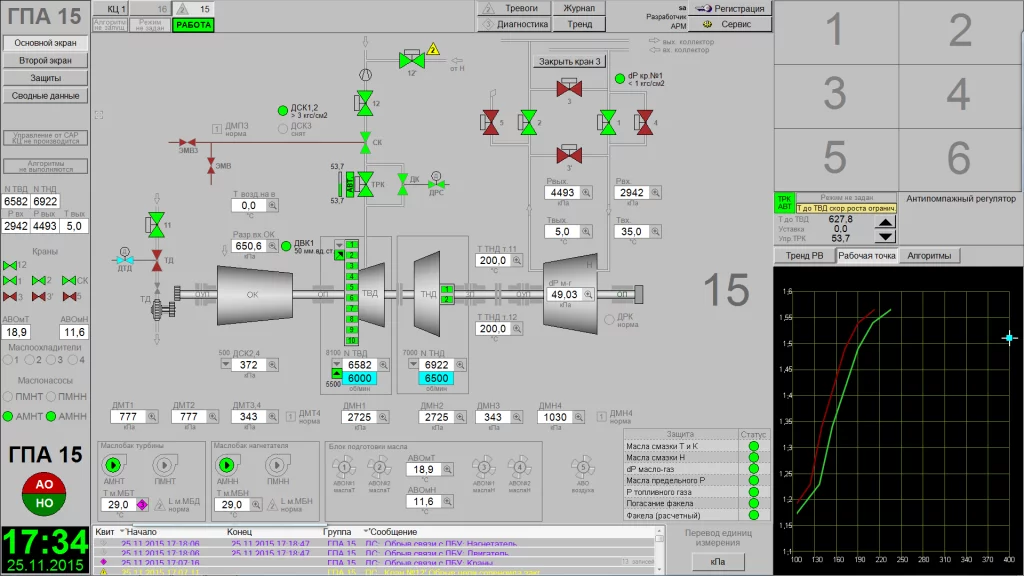

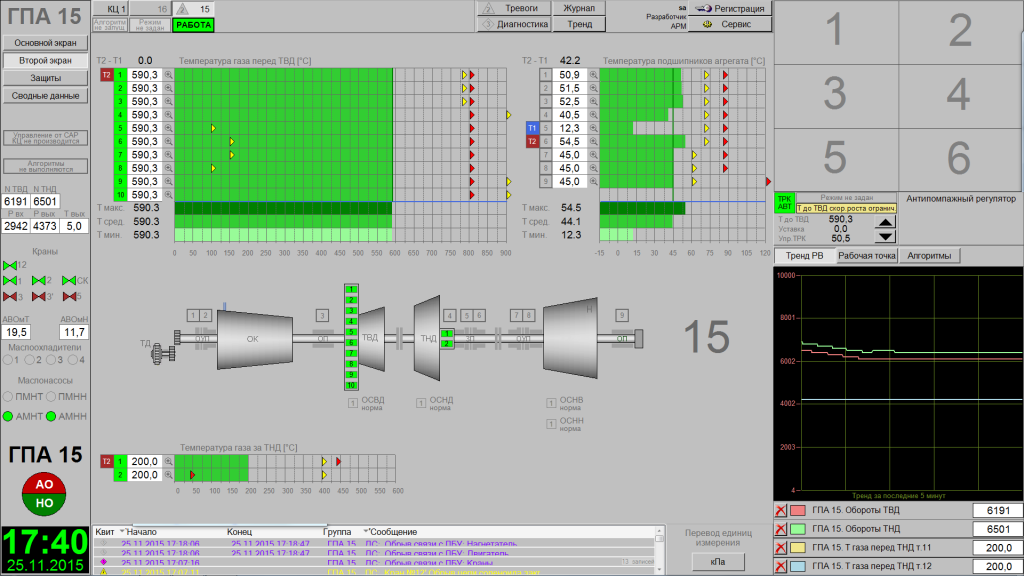

The automated control system comprises:

- 7 main control cabinets (CC, communication, connection node, 2 I/O cabinets, server rack, backup panel)

- GPA control systems with power distribution, communication, motor, compressor, and valve control units

System components include:

- Fastwel MK-150 controllers

- Fastwel I/O periphery

- Nutrino real-time OS

- ISaGRAF 6 development environment

- Ethernet/UDP and Modbus RTU communication protocols

- Custom OPC server

- MasterSCADA for flexible control

Technical specifications:

- 800 I/O signals, 5 interface channels

- 7,800 tags

- 150 alarms

- 240 archived trends (250 ms period)

- Redundant server with 2 workstations and Firebird DBMS

System functions

The MasterSCADA software installed in automated workplaces provides the following functions:

Result

The system operates in continuous mode. It meets all requirements of Gazprom's Corporate Standards (STO) for the Compressor Shop Process Control System (ACS TP KS) and the Gas Pumping Unit Automated Control System (SAU GPA). MasterSCADA IDE training, along with the development of generation scripts, visual functional blocks, and the application project, took one year to complete. Two control systems engineers with experience in industrial automation development were involved in the project. Commissioning took two months, and system refinement is ongoing during the pilot operation phase.