Mining

October 2023 г.

System purpose

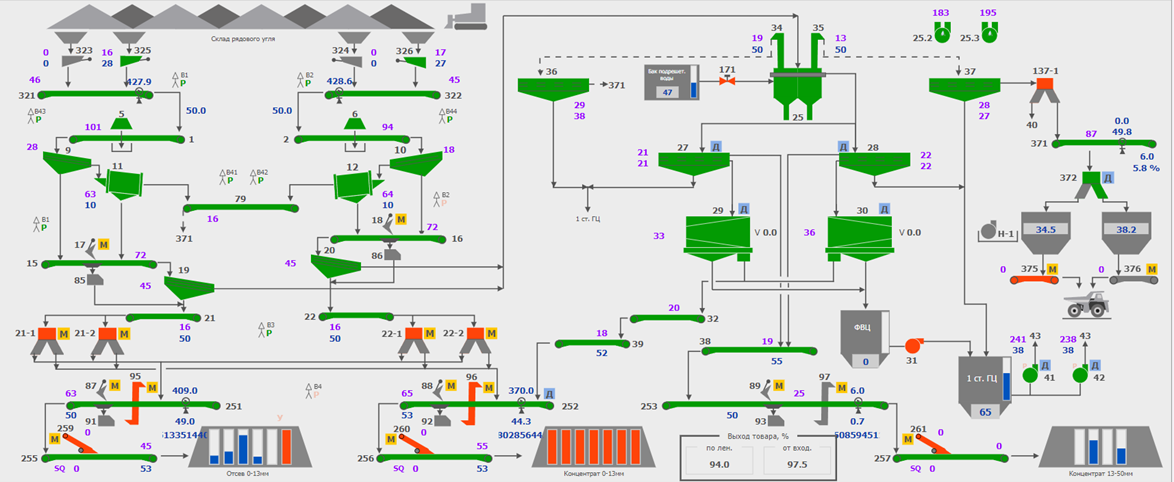

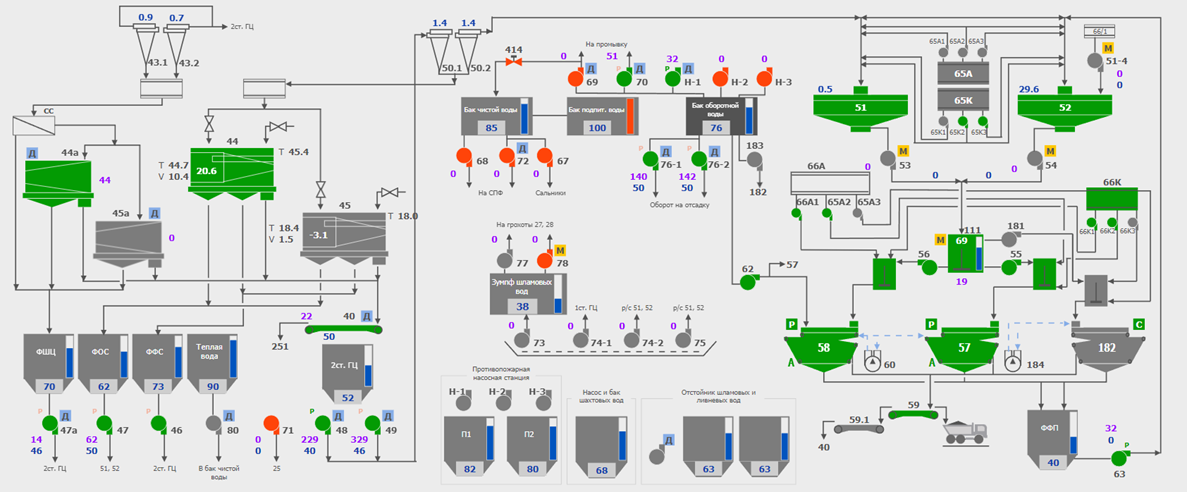

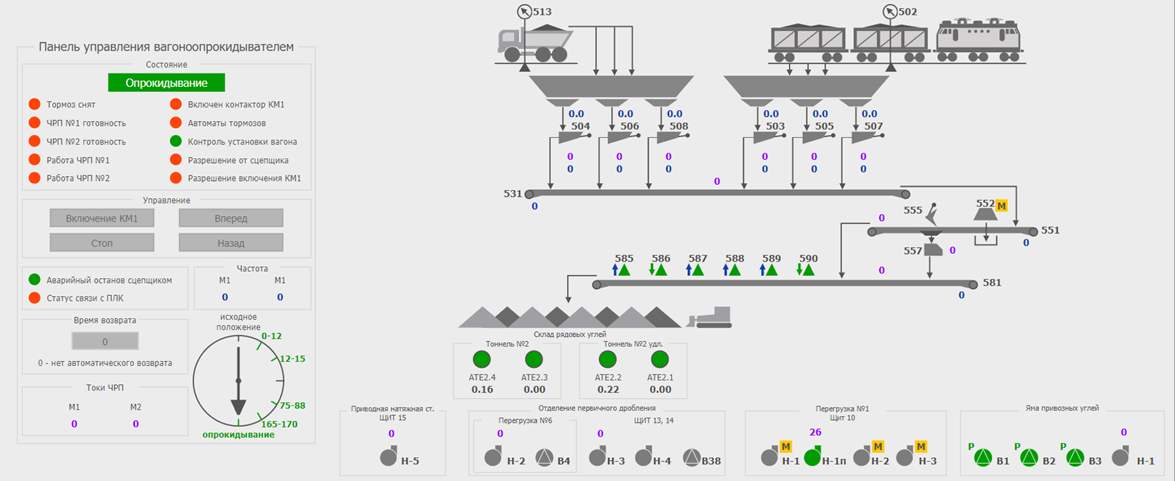

The computerized process control system for coal beneficiation is designed to manage and monitor technological processes at the Listvyazhnaya processing plant. The system ensures efficient coal flow management, enhances production safety, and optimizes resource utilization.

Computerized process control system (CPCS) was developed for a coal beneficiation facility.

Task of implementing the new system

The primary objective of implementing the new system is to replace the outdated SCADA system with the modern and secure MasterSCADA 4D platform.

The implementation of the new system also included a number of other goals:

Ensuring high-level reliability and uninterrupted operation of the automation system;

Implementation of remote access for operators;

Enhancing the level of safety and control over technological processes through the implementation of additional equipment control blocking capabilities;

Interface improvement considering modern trends and customer requirements.

Solution

As part of the project implementation, it was decided to use the domestic MasterSCADA 4D system, which ensured compliance with information security requirements and eliminated risks associated with sanctions. The main system components include: MasterSCADA 4D with 60,000 external I/O points, client workstation packages, as well as drivers for the SNMP and Siemens Profinet protocols.

System functions

The MasterSCADA software installed in automated workplaces provides the following functions:

Network monitoring;

Monitoring of Programmable Logic Controllers (PLCs): Continuous monitoring of PLC operation ensures stable functioning of technological processes and instant response to any deviations;

Monitoring of Uninterruptible Power Supplies (UPS): The system allows monitoring of UPS status, which is critically important for maintaining equipment operability under unstable power supply conditions;

Flexible interface configuration: Allows adaptation of dispatcher and operator workstations to specific user needs, improving usability.

Result

Following the implementation of the new automation system at the Listvyazhnaya processing plant, the following results were achieved:

- Complete replacement of software with a domestic equivalent – MasterSCADA 4D, which ensured compliance with information security requirements and eliminated risks associated with sanctions.

- Migration of all algorithms for raw material calculations and shipments, which preserved and enhanced the efficiency of production processes.

- Redesign of the system interface considering Customer feedback and modern trends ("Dark Mode"), improving the usability and functionality of operator workstations.

- Implementation of additional equipment control lockout capabilities, increasing the safety level and control over technological processes.