Heat&Power

December 2017 г.

System purpose

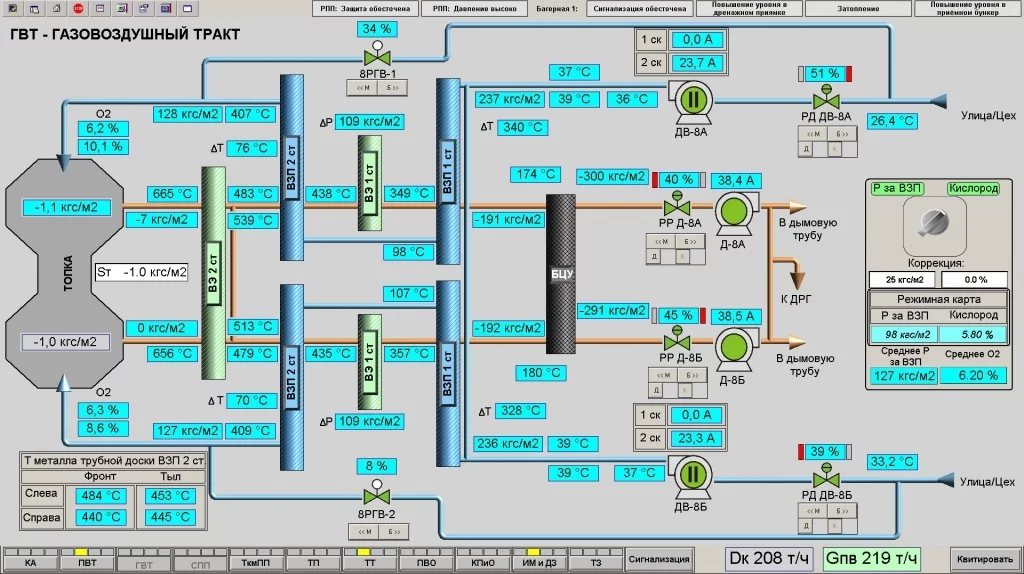

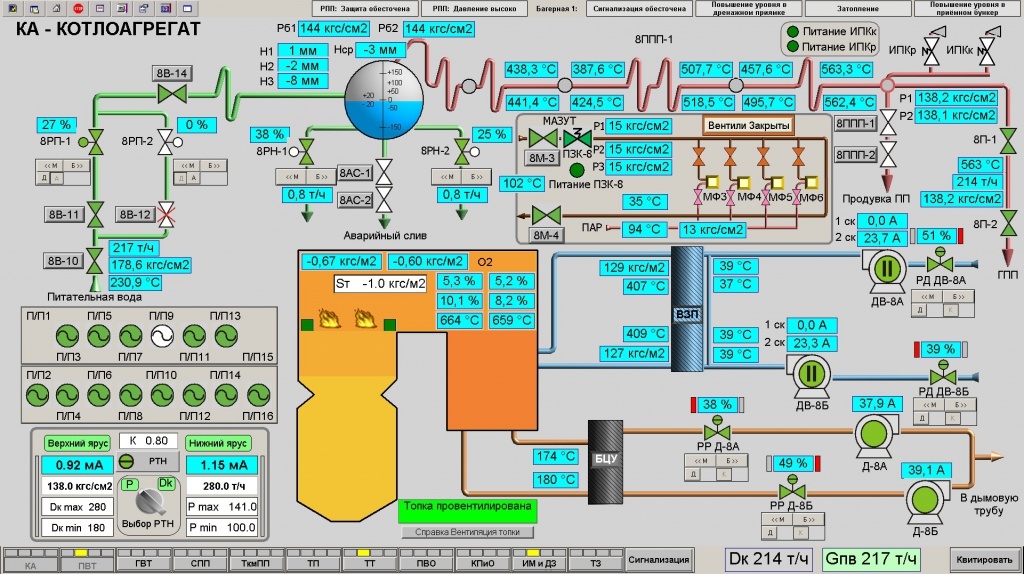

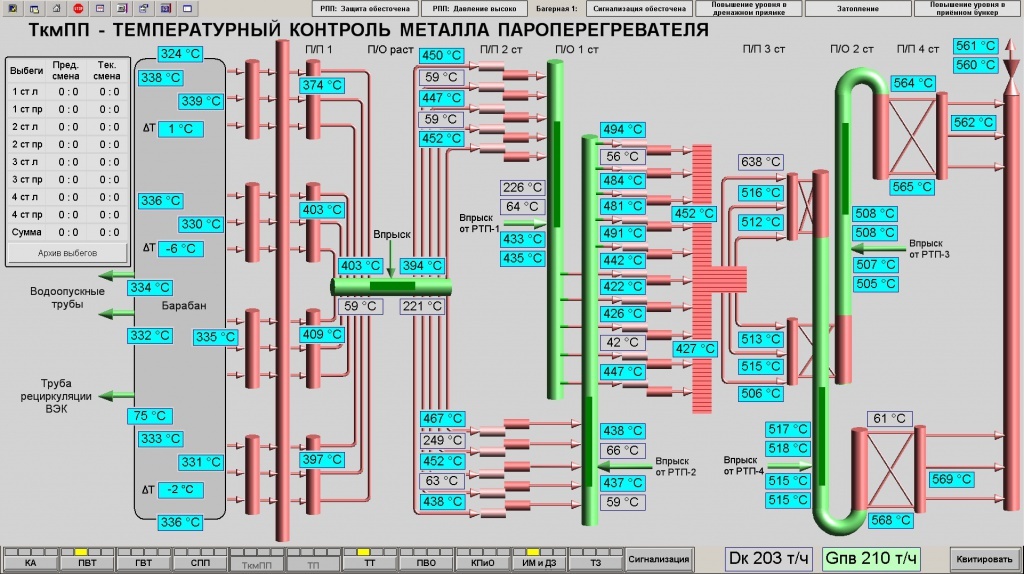

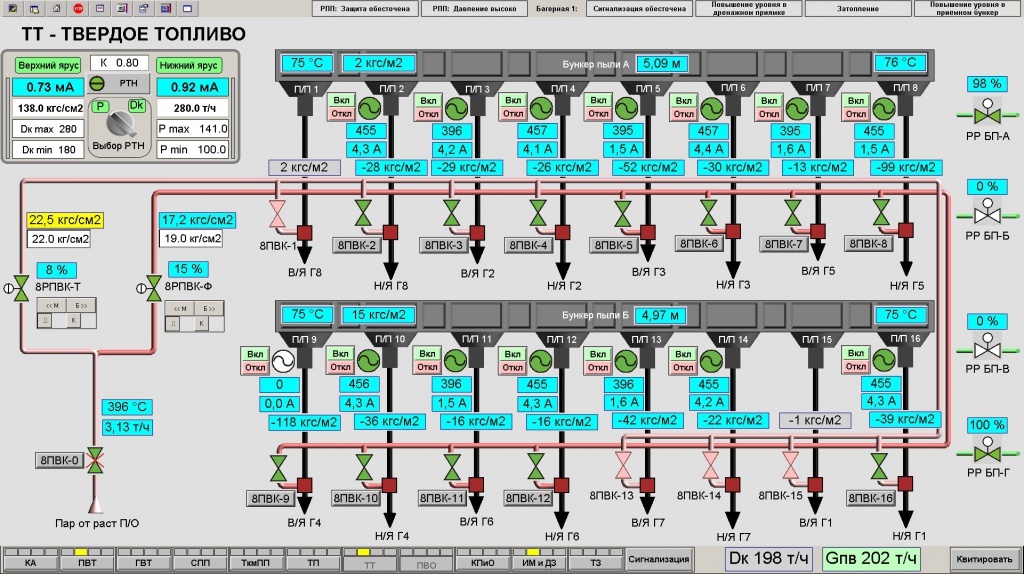

A full-scale Process Automation System (PAS) has been implemented, which includes a Boiler Unit (BU) Automatic Control System (ACS), an interlock and protection system, and a technical heat accounting system. The PAS provides operational data support for shift operators, technical staff, and management; performs automatic control of the boiler unit equipment; and allows for the configuration of setpoints in automatic mode. This system represents an extension of previous ACS implementation projects, utilizing the same software and hardware platform on other boiler units within the plant.

Task of implementing the new system

Boiler unit optimization via modern control & protection systems to enhance efficiency and reliability.

The implementation of the new system also included a number of other goals:

Integration with existing systems;

Reduced equipment downtime;

Enhanced sustainability through emission reduction;

Deployment of an external data aggregation platform.

Solution

Irkutskenergo JSC is one of the largest energy companies in Russia, ranking third among Russian companies in electricity generation and second in heat energy production. The system consists of an engineering station and two equivalent operator workstations (industrial computers from ICP Electronics with two 20-inch monitors). The TECON MFC3000 controller was chosen as the core platform for the Process Control System (PCS). These controllers are connected to the workstations via a redundant Industrial Ethernet network (using Moxa EDS405 switches). Additionally, the workstations poll a Wincon controller with Teconic remote temperature input modules and TST11 intelligent sensors (both from TECON).

Monitoring of station service mechanisms (consumed power and current) is performed by BEMP units connected to the same controller. The interlock and protection controller is fully redundant (some analog inputs are triplicated), while in the automatic control system (ACS) controller, only the processors and power supply units are duplicated.

The workstations are also connected to the plant-wide Ethernet network to provide access to the system from the upper-level and for data transfer to an external database. The technical heat accounting system is implemented on a Wincon controller, to which SPT961 heat calculators ("Logika") are connected.

The software for the workstations and controllers is the vertically integrated SCADA and Softlogic system MasterSCADA, which includes functions for metrological verification, equipment certification, and support for Internet clients. The engineering station additionally has the PID-Expert tuning system software installed. The external database is MS SQL Server.

System functions

The MasterSCADA software installed in automated workplaces provides the following functions:

Automated control of boiler unit equipment with maintenance of set parameters across all operational modes, including start-up, base load, and within the boiler's modulating range;

Logical control of process equipment;

Safe shutdown of main and auxiliary equipment during emergency situations (process safety interlocks);

Remote actuation of final control elements;

Automated start-up and shutdown procedures for process equipment;

Continuous diagnostics of connected equipment and self-diagnostics;

Data export to the high-level system.

Result

The outcomes of the implementation include an increase in boiler unit efficiency due to more optimal process control, a reduction in process equipment downtime through enhanced system reliability, a decrease in harmful emissions, and lowered production and operational costs driven by improved fuel efficiency.