System purpose

The implementation of the new system was aimed at creating a unified, reliable solution for managing the shopping center's engineering systems. The primary objectives included centralizing control over ventilation, lighting, heating, and water supply, minimizing manual intervention, improving energy efficiency, and enhancing operational safety through the monitoring of critical parameters.

The implementation of the new system also included a number of other goals:

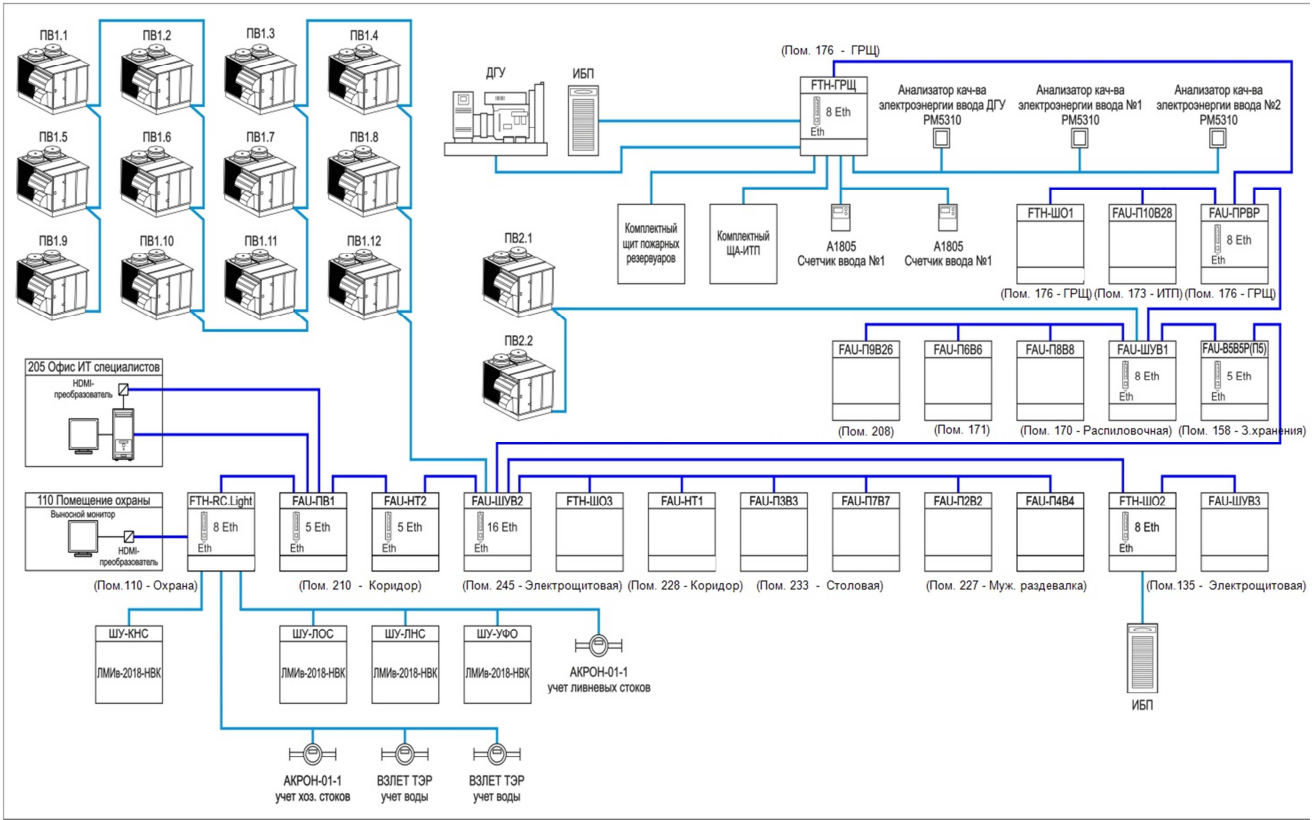

Solution

System functions

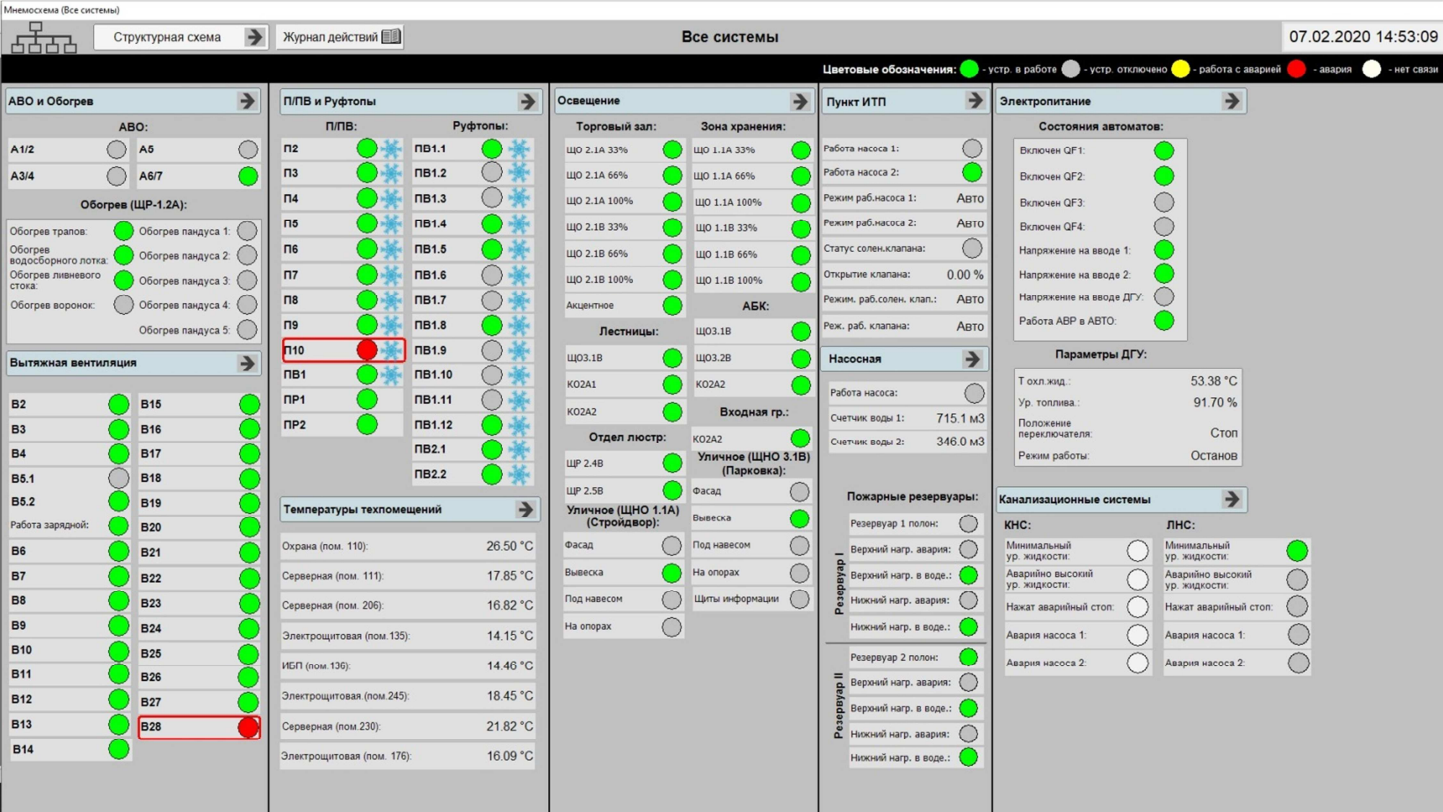

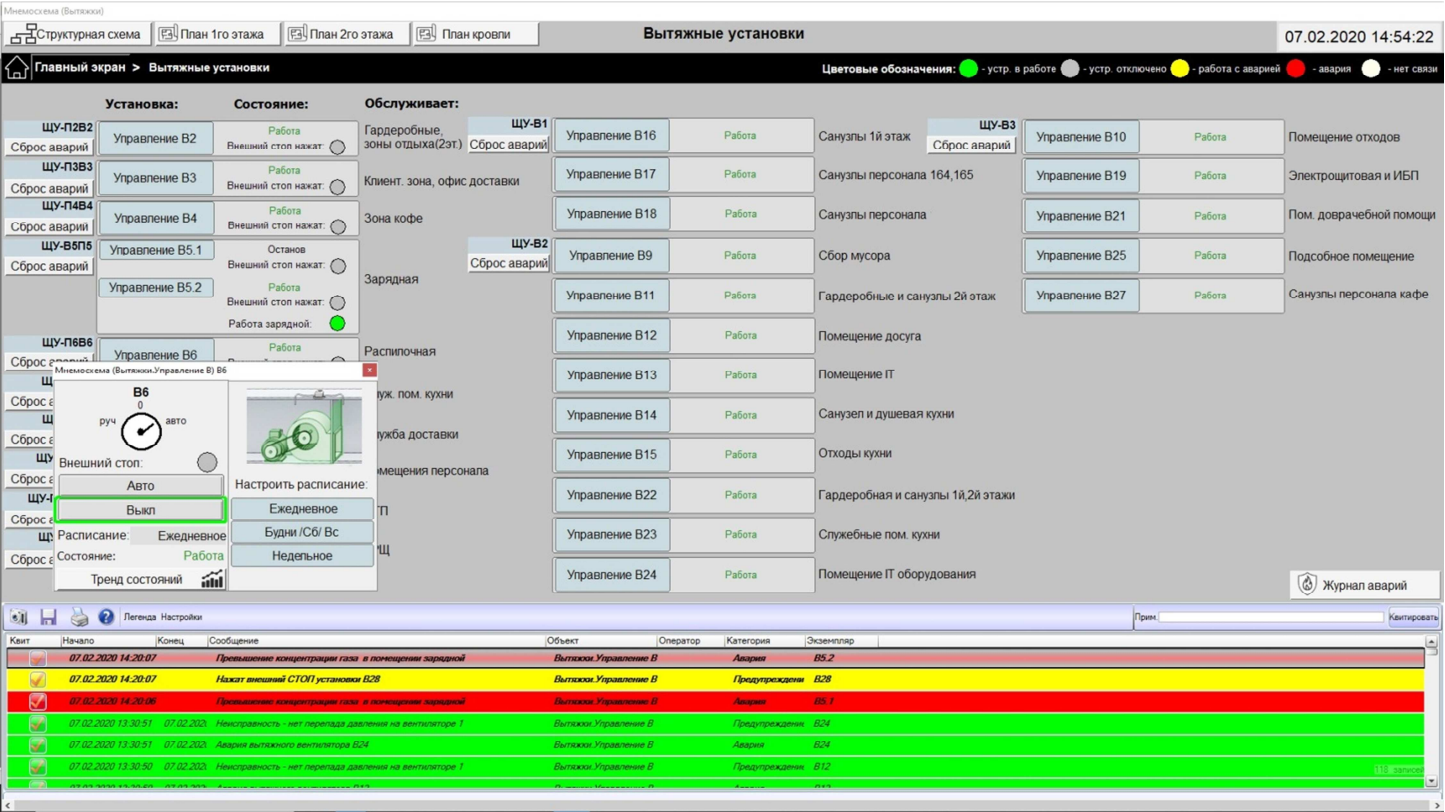

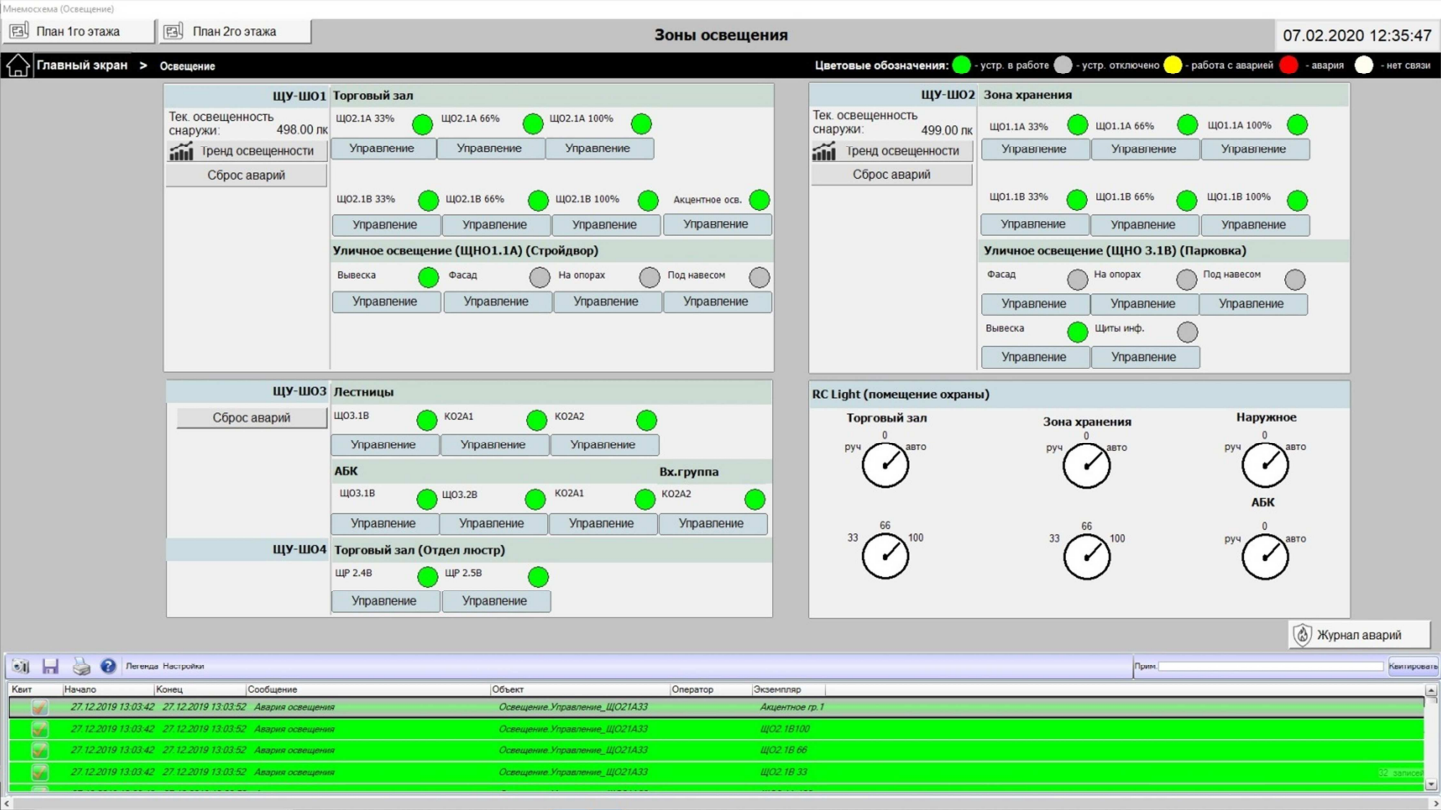

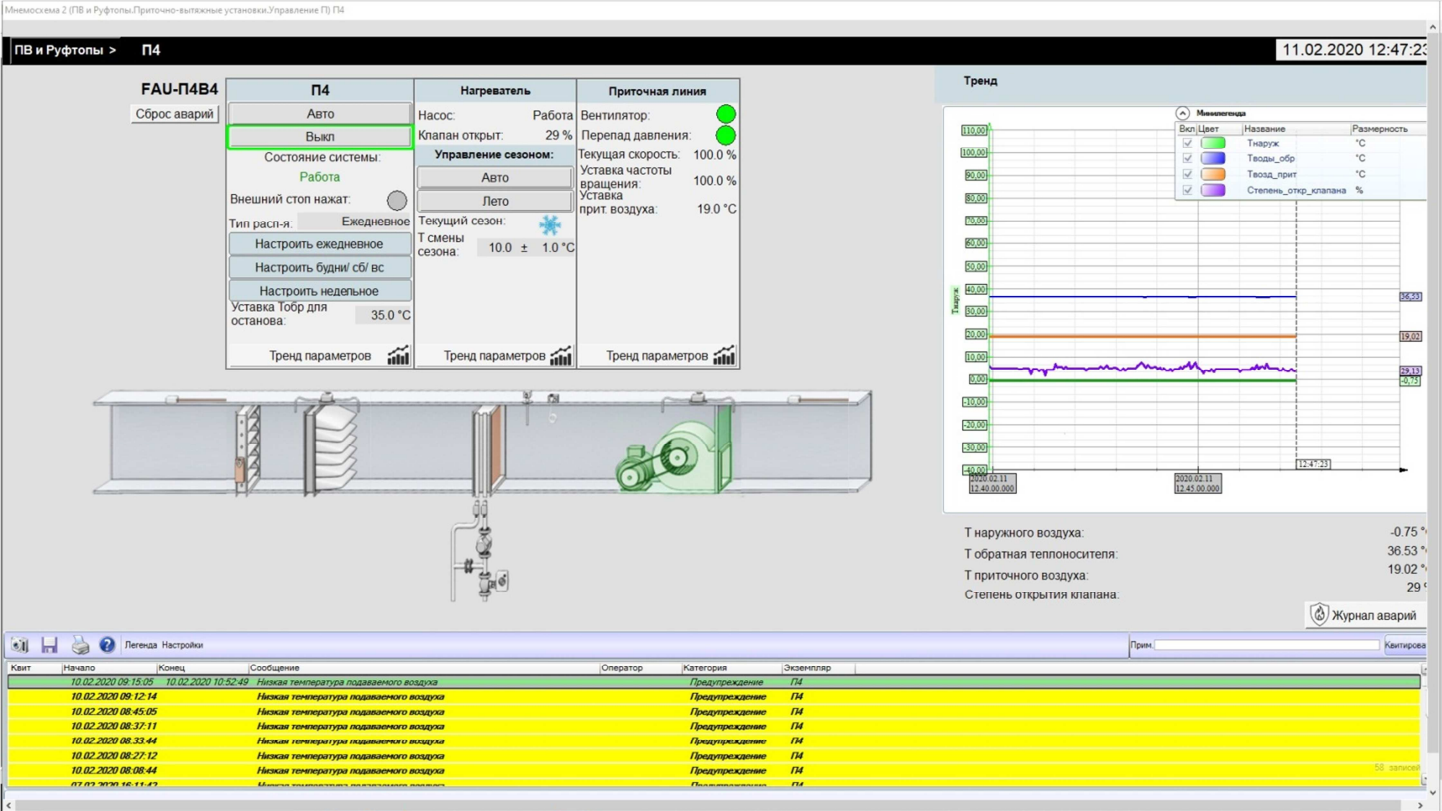

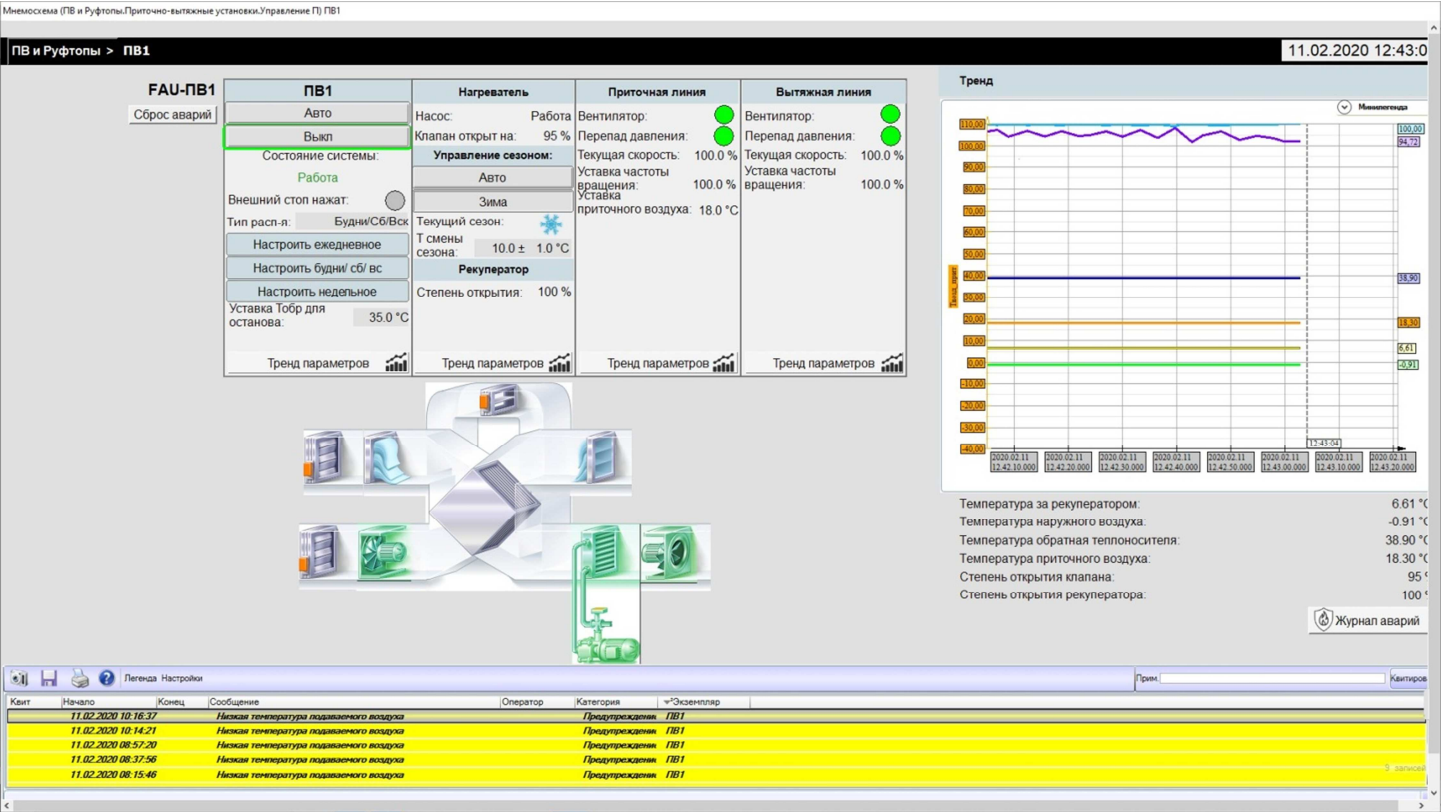

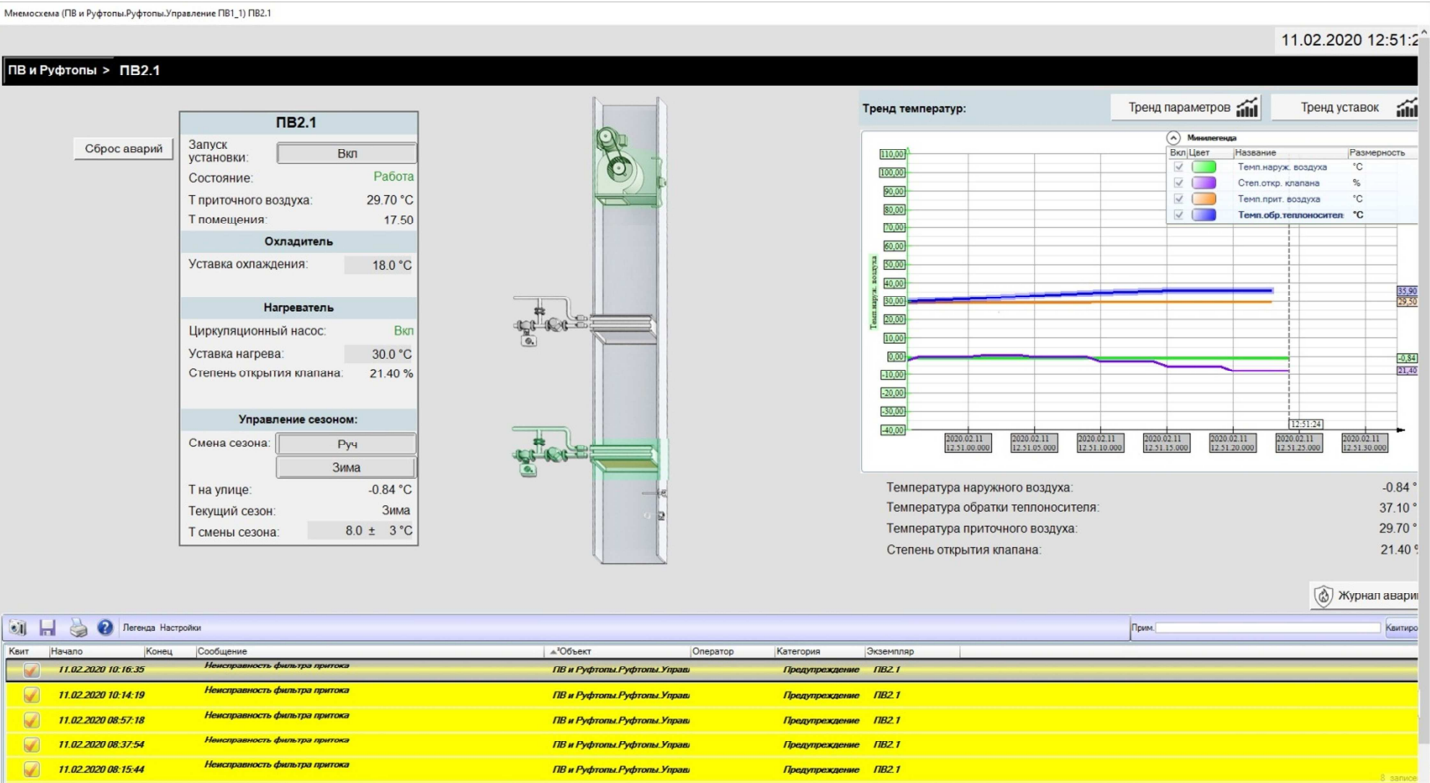

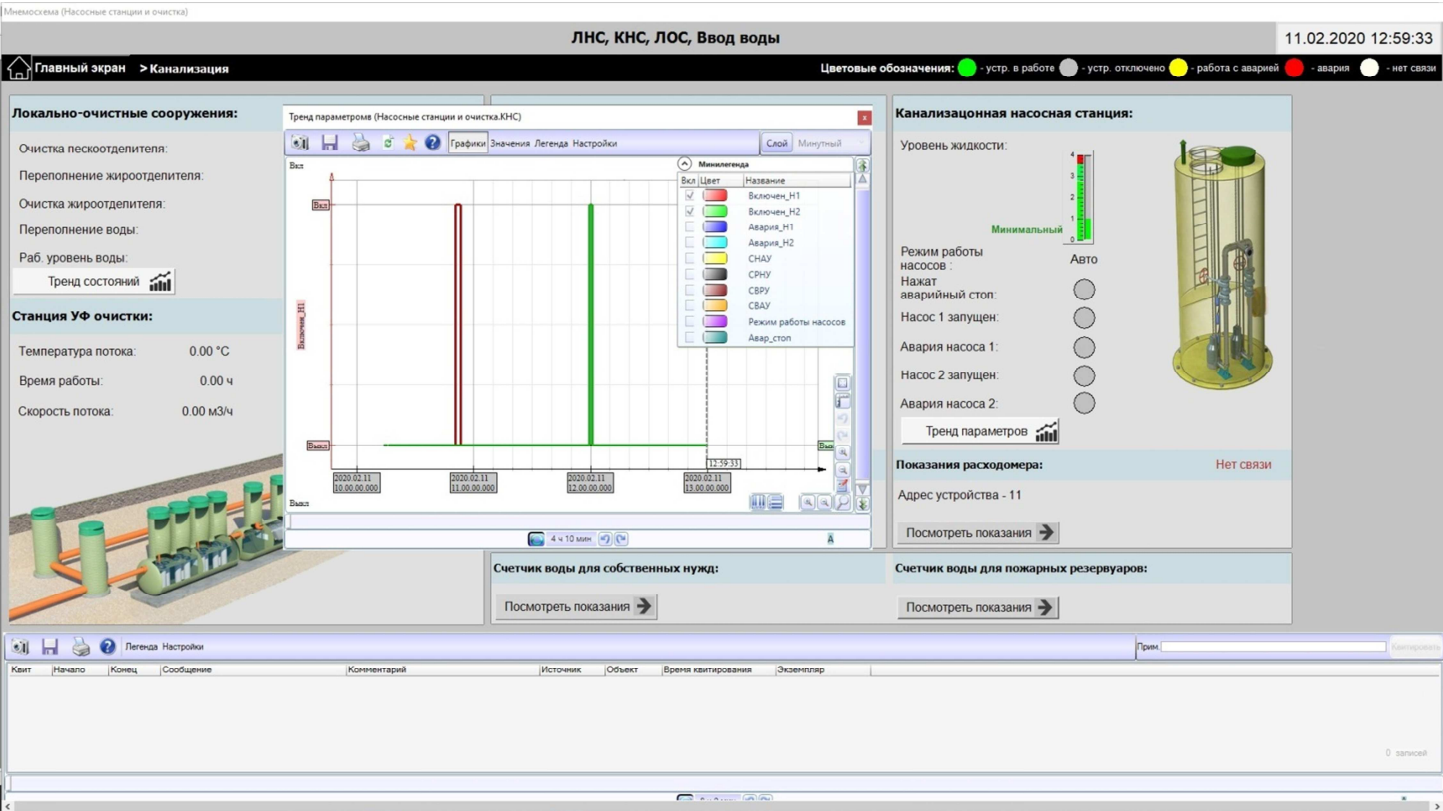

The MasterSCADA software installed in automated workplaces provides the following functions:

Result

The system implementation provides engineers with real-time operational visibility into all facility systems. The platform enables remote control of automated equipment, access to historical data archives, and trend analysis capabilities. Furthermore, through deep operational analytics and equipment performance optimization, the system significantly enhances operational reliability while reducing operating expenditures (OPEX).