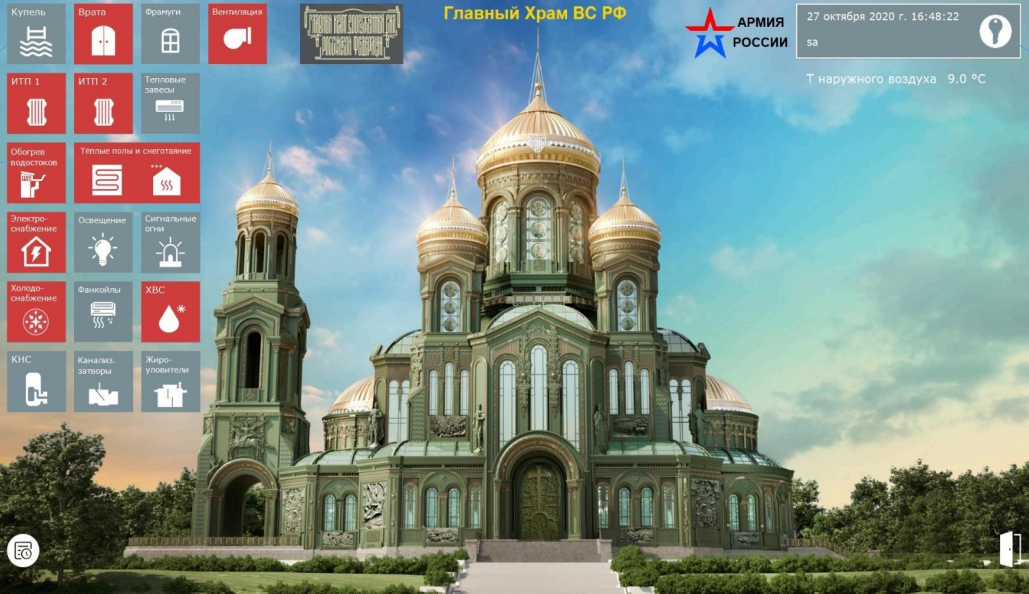

System purpose

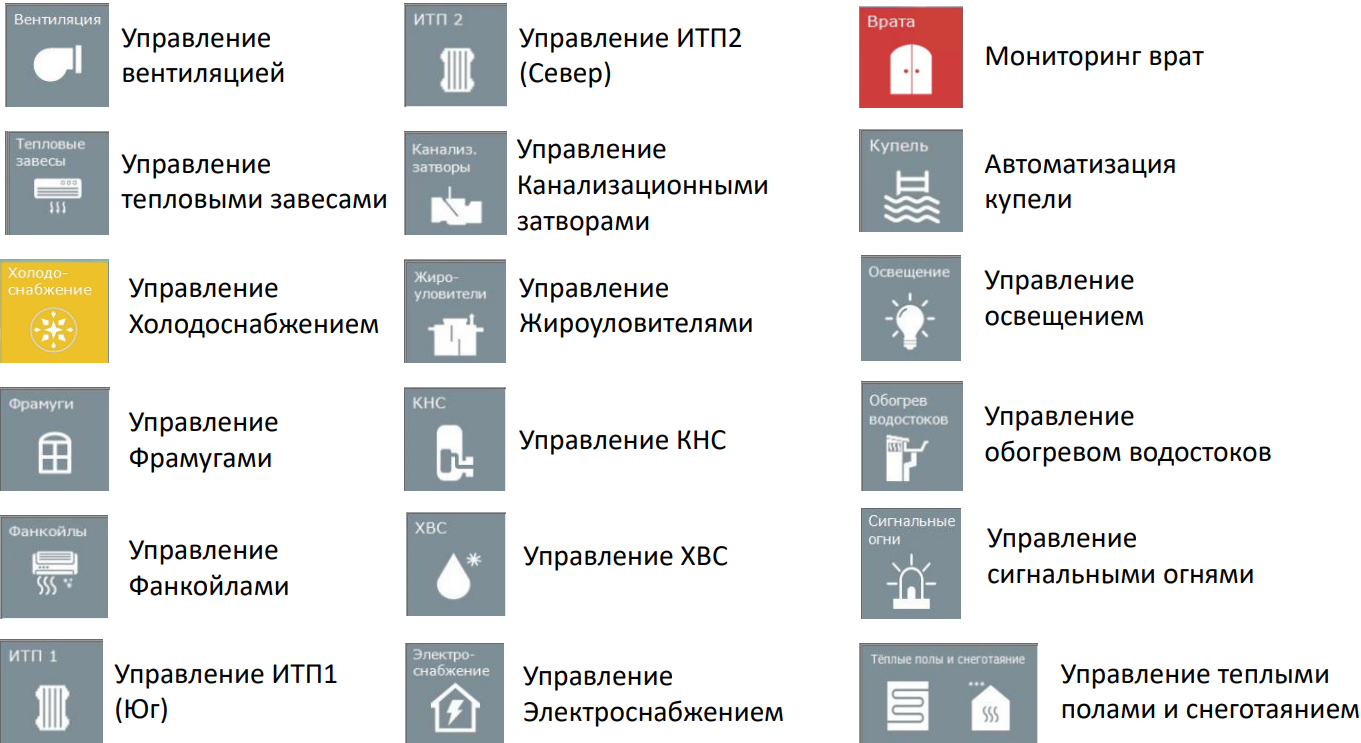

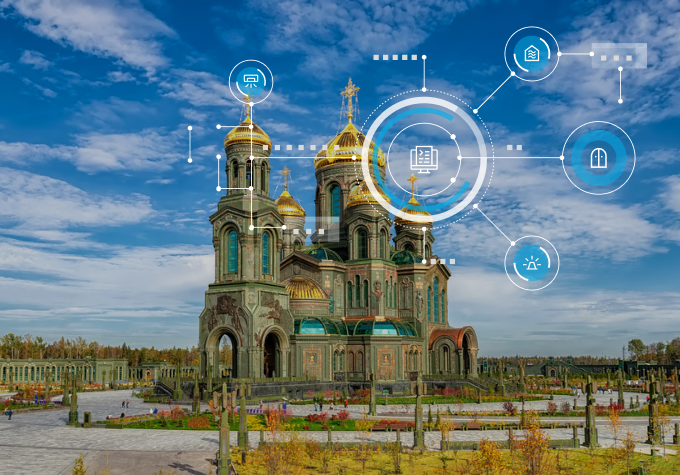

The system provides comprehensive control over the following functions:

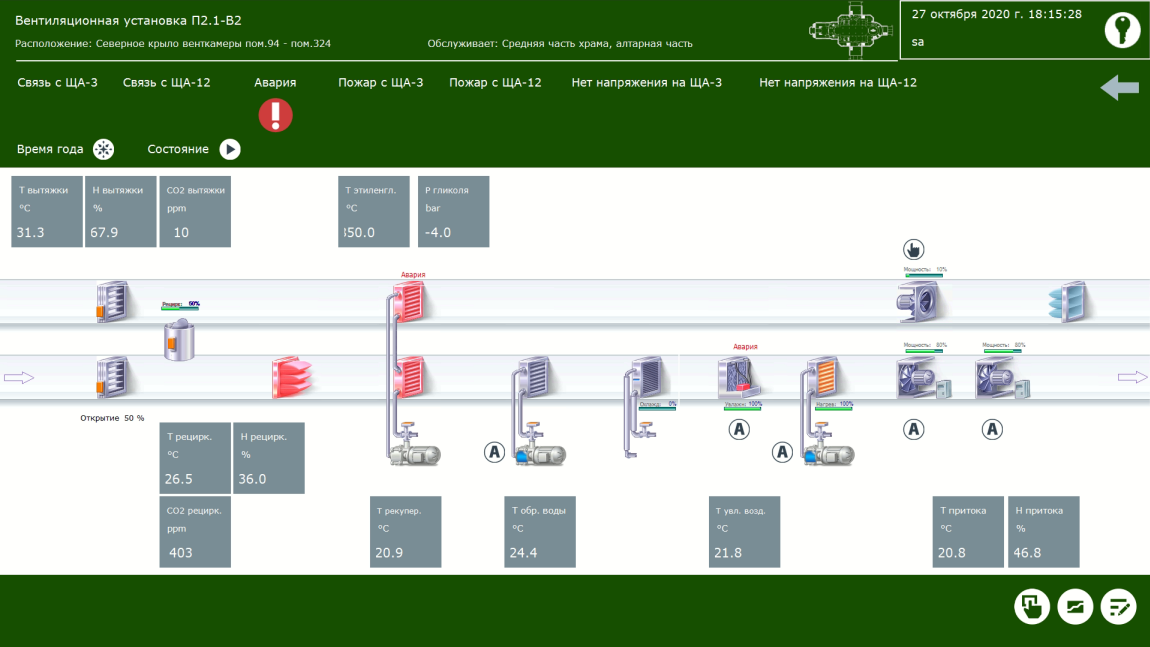

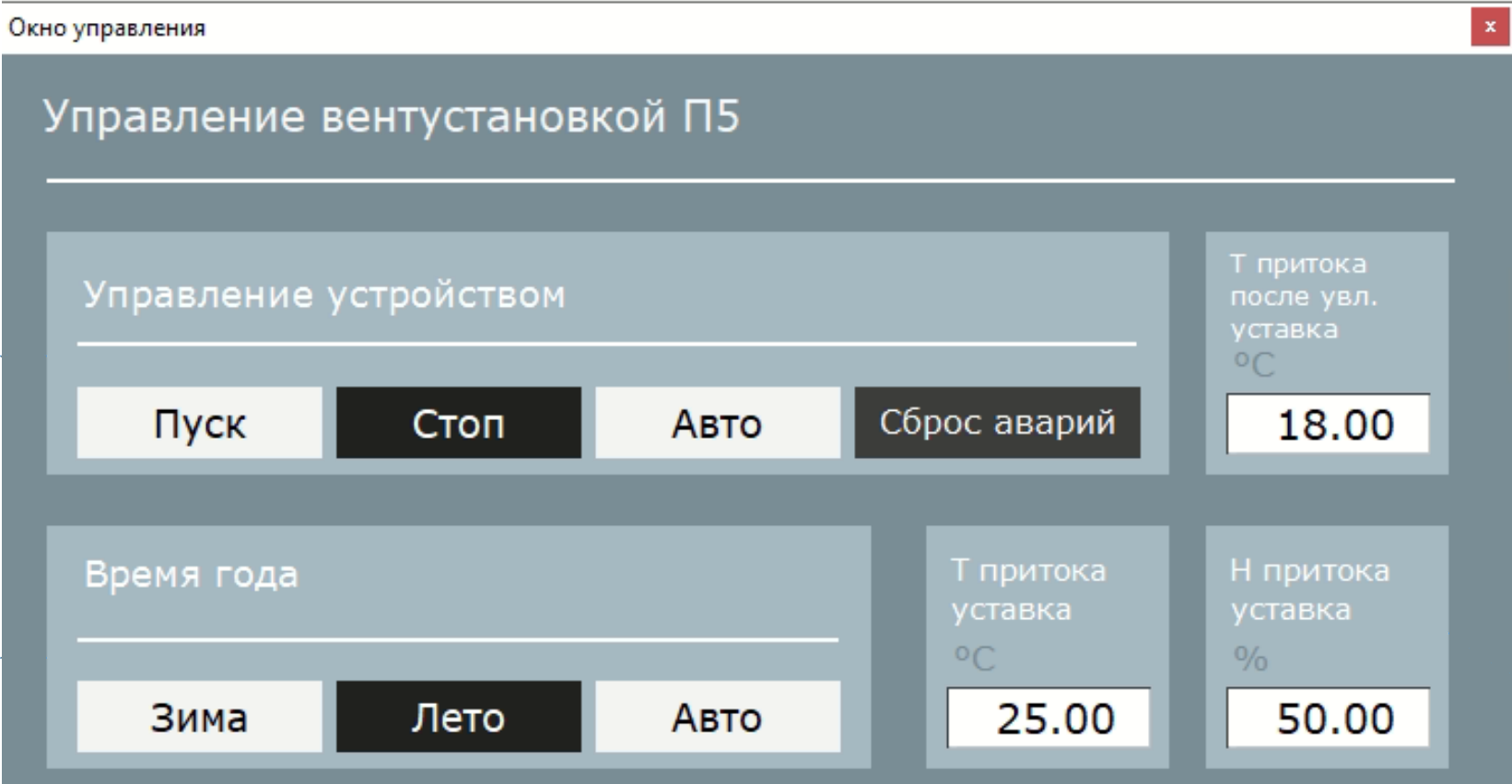

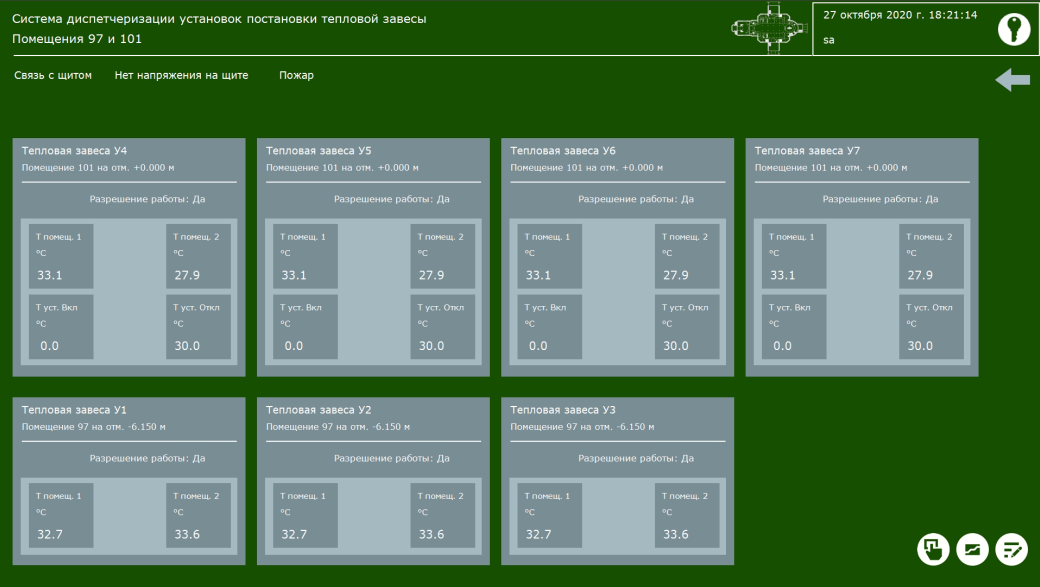

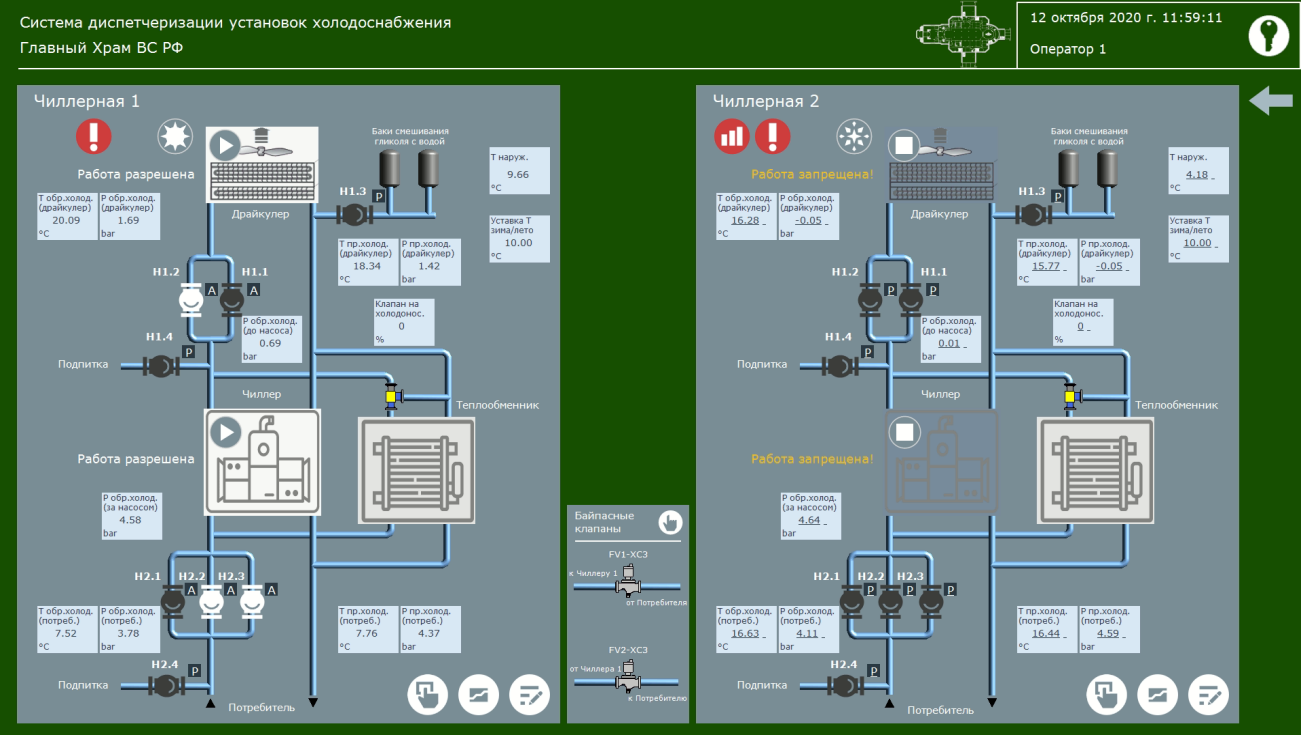

HVAC and Climate Control: Ventilation management, thermal curtains, cold supply systems, louver control, fan coil units.

Utility Plant Control: Management of ITP1 (South) and ITP2 (North) individual thermal points.

Waste Management Systems: Control of sewage gates, grease traps, wastewater pumping stations (WWPS), cold water supply (CWS), and electrical systems.

Additional Functions: Gate monitoring, baptismal font automation, lighting control, gutter heating, signal lights, underfloor heating, and snow melting systems.

The implementation of the new system also included a number of other goals:

Solution

System functions

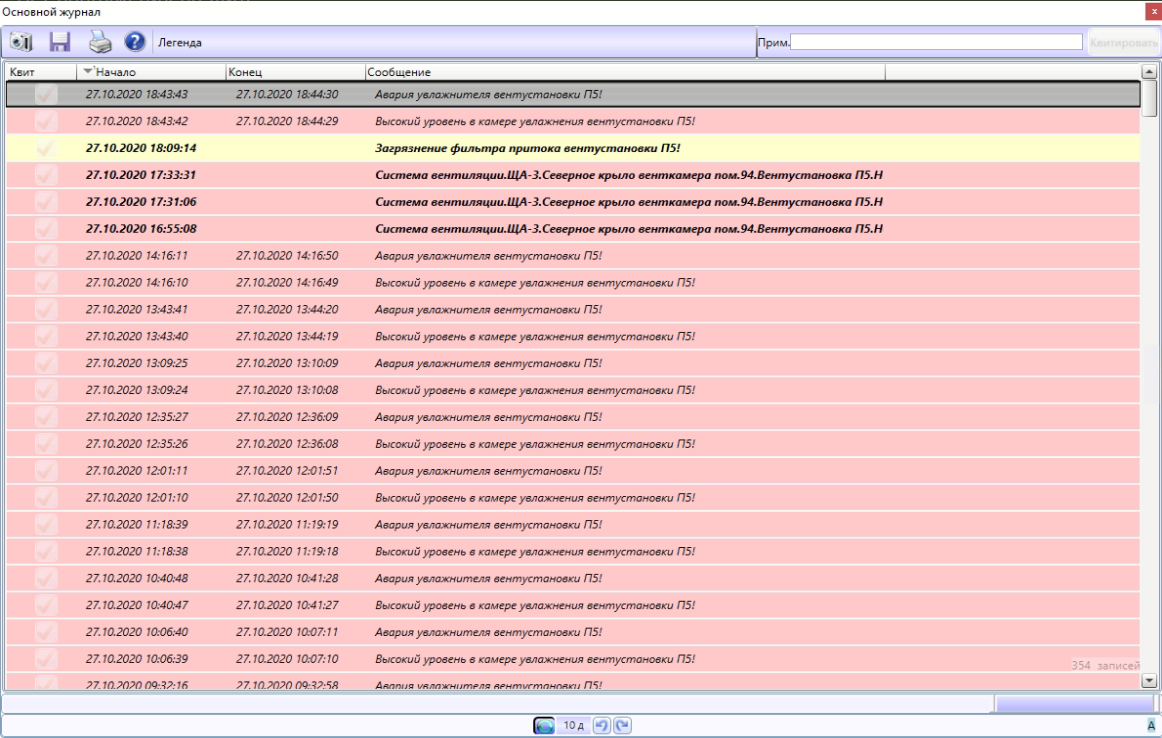

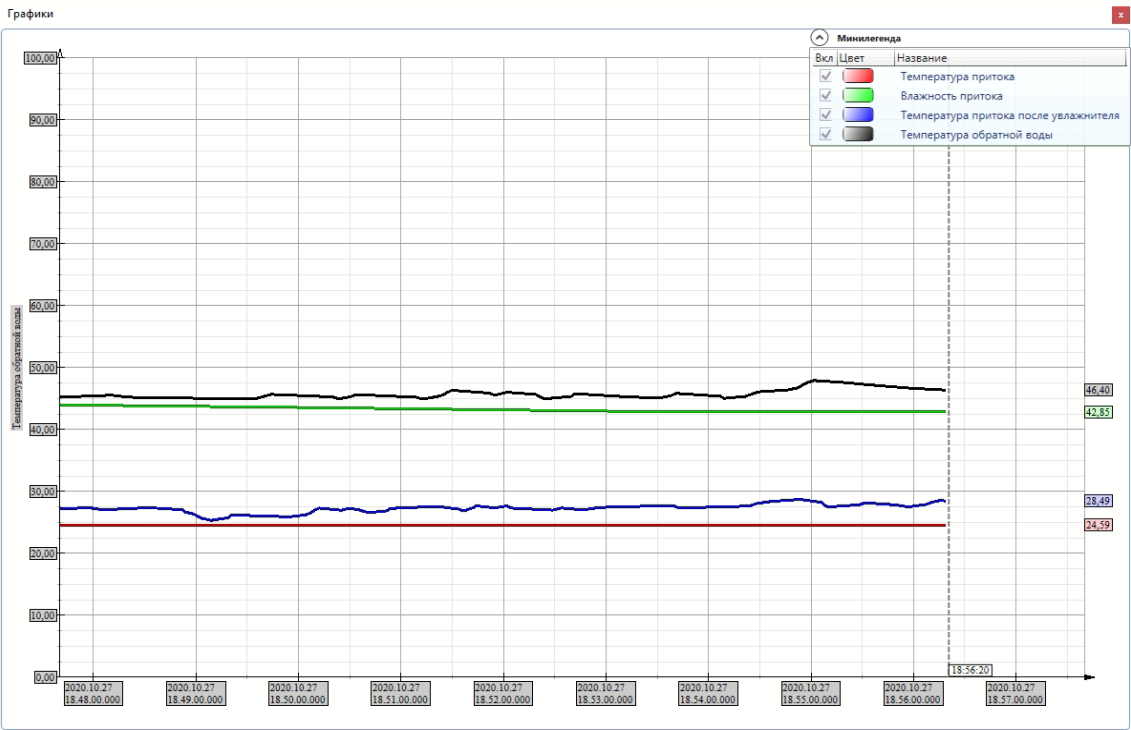

The MasterSCADA software installed in automated workplaces provides the following functions:

Result

The system implementation resulted in a 70% reduction in labor costs and up to 25% savings in material resources. Work completion time was cut by more than half due to the integrated operation and centralized dispatching of approximately fifteen life-support systems. The system processes over 3,000 signals and integrates roughly 11 subsystems, substantially improving the efficiency of cathedral infrastructure maintenance, work planning, and staff coordination.