System purpose

A process control system built on a SCADA platform has been implemented for centralized monitoring and management of the energy complex at the Kumroch mining and processing plant. The MasterSCADA-based solution enables effective equipment performance tracking, control of power generation and heat recovery processes, and storage of critical data for subsequent analysis and optimization.

The implementation of MasterSCADA software was driven by the need to meet the requirements of the technical assignment, including the mandatory use of Russian software. The choice of MasterSCADA 4D allowed for the realization of the declared functional requirements and ensured reliable control of technological processes at the new facility.

The implementation of the new system also included a number of other goals:

Solution

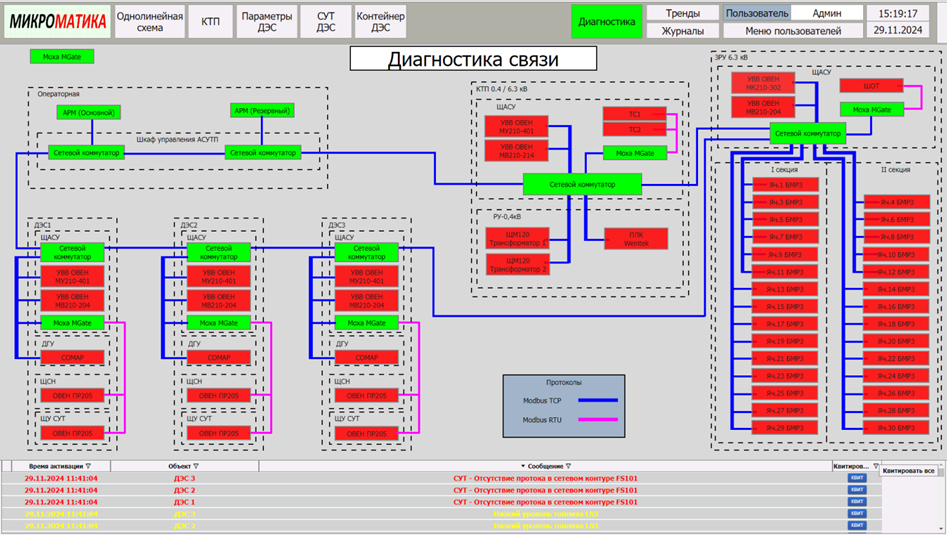

The system is built on a two-level topology that ensures reliable and efficient interaction between components. The upper level includes two operator workstations (primary and backup), deployed on Windows 10 OS using MasterSCADA 4D software. These workstations interact with middle-level equipment via the Modbus TCP protocol.

The middle level is represented by diverse equipment, including ComAp generator controllers, Moxa Mgate Modbus gateways, OWEN 2XX-series I/O devices, OWEN PR205 intelligent relays, BMRA protection and automation relay terminals, and PLCs for local heat recovery control systems.

The system processes data from 1500 points, ensuring their collection and transmission between levels. This approach enabled the creation of a structured and functional architecture capable of effectively solving the energy center's tasks.

The implementation stages included: analysis of technical specification requirements, selection of MasterSCADA 4D license, creation of automation objects, development of mnemonic diagrams, configuration of archives, and commissioning works at the customer's site.

System functions

The MasterSCADA software installed in automated workplaces provides the following functions:

Result

The implementation of the system based on MasterSCADA 4D has achieved significant improvements in energy center management. The number of unplanned equipment shutdowns has decreased, positively impacting the overall reliability of the energy center's operation. Economic efficiency was achieved through the reduction of losses associated with downtime and decreased equipment maintenance costs, while the simplicity of planning and executing technical maintenance helped optimize operational expenses. Thus, MasterSCADA 4D has proven its effectiveness as a tool for enhancing the productivity and reliability of the energy center.