System purpose

The EMS System (Cleanroom Environmental Parameter Monitoring) is designed to automate the monitoring and control of critical environmental parameters (temperature, humidity, pressure) in cleanroom facilities utilized by Valenta Pharm in its production processes. The system ensures compliance with stringent quality and safety standards by maintaining precise control over critical production environment conditions.

In response to licensing and customs restrictions, the company opted for the MasterSCADA platform to eliminate dependence on foreign components and software solutions. This strategic decision provides several key advantages:

- System Reliability: ensuring consistent performance and operational stability

- Flexibility: adaptability to evolving production requirements

- Independence: technological sovereignty and reduced vulnerability to external restrictions

- Risk Mitigation: minimization of sanctions-related challenges

- Operational Resilience: enhanced business continuity capabilities

By implementing this domestic solution, the company has strengthened its position in the market while maintaining compliance with regulatory requirements and ensuring uninterrupted production operations.

The principal project objective for Valenta Pharm involved the development of an advanced environmental control system designed to continuously monitor and maintain critical cleanroom parameters (temperature, humidity, pressure) — essential for ensuring compliance in pharmaceutical manufacturing environments. The system architecture was engineered to deliver comprehensive process management capabilities while addressing strategic business requirements.

System Functional Requirements:

Automated Process Control: implementing real-time response mechanisms for immediate adjustment of process equipment in response to parameter deviations from established setpoints. Operational Independence: reducing reliance on external influences and foreign-sourced automation components through localized solutions. System Scalability: enabling seamless expansion of monitored assets with optimized resource allocation and minimal incremental costs. Technology Sovereignty: integrating domestically produced hardware components and software applications immune to external restrictions or supply chain disruptions.

This strategic approach to environmental control not only ensures precise maintenance of critical manufacturing parameters but also supports the company's long-term goals of operational autonomy and technological resilience in the competitive pharmaceutical industry landscape. The solution provides a robust foundation for sustainable growth while maintaining compliance with stringent industry standards.

The implementation of the new system also included a number of other goals:

Solution

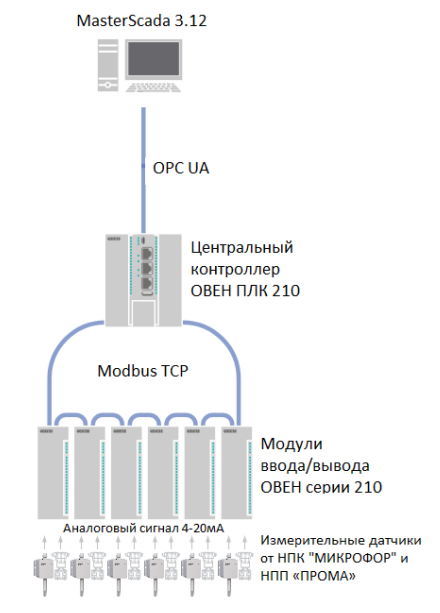

EMS Project Architecture

The automation system is structured in a hierarchical architecture with three primary levels of operation. At the field level, sensors deployed throughout the monitored facilities collect critical environmental data, including temperature, humidity, and pressure readings. These measurements are then transmitted to the control level, where dedicated controllers process incoming signals, perform necessary calculations, and forward the processed data to the upper tier of the system.

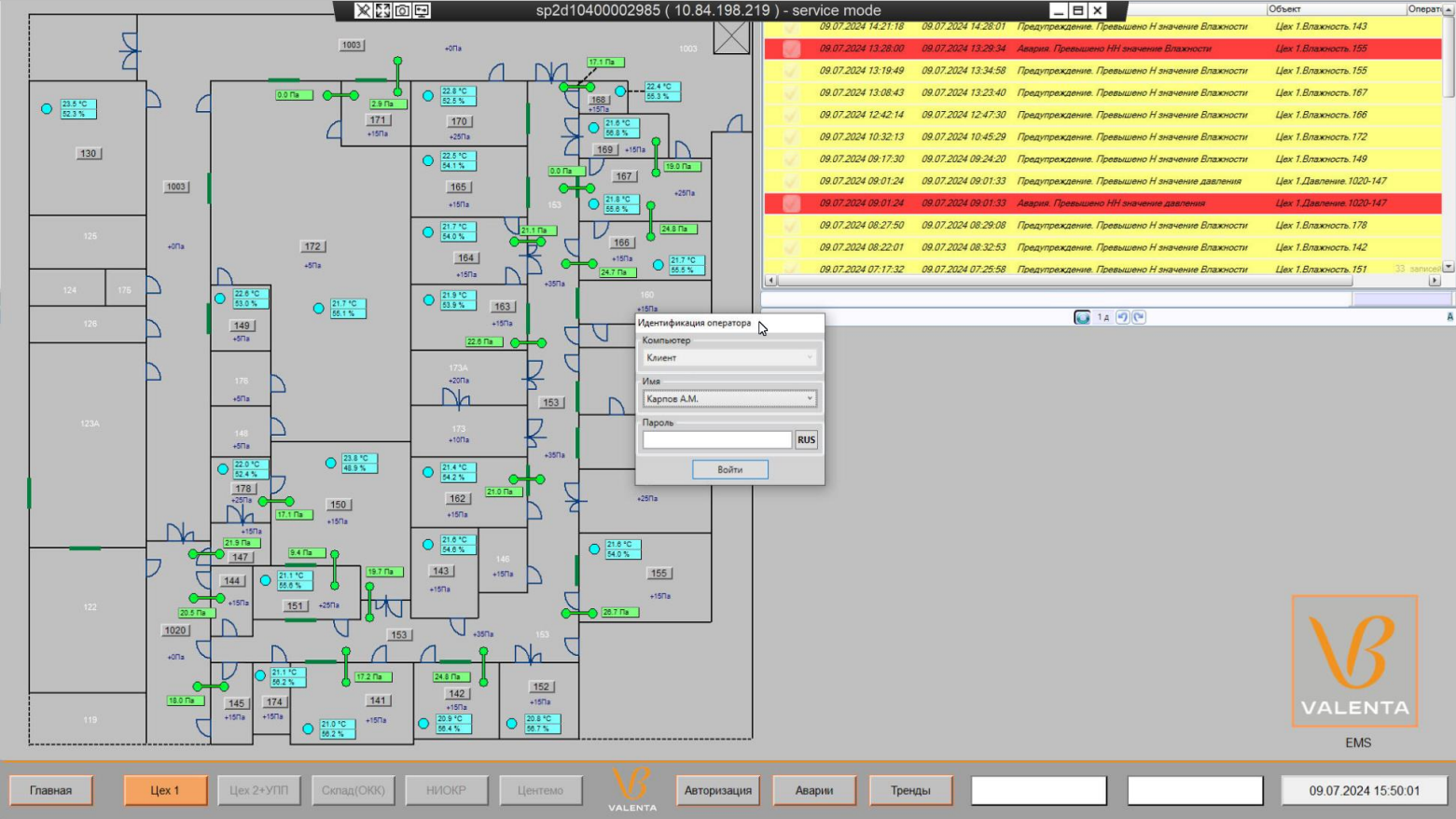

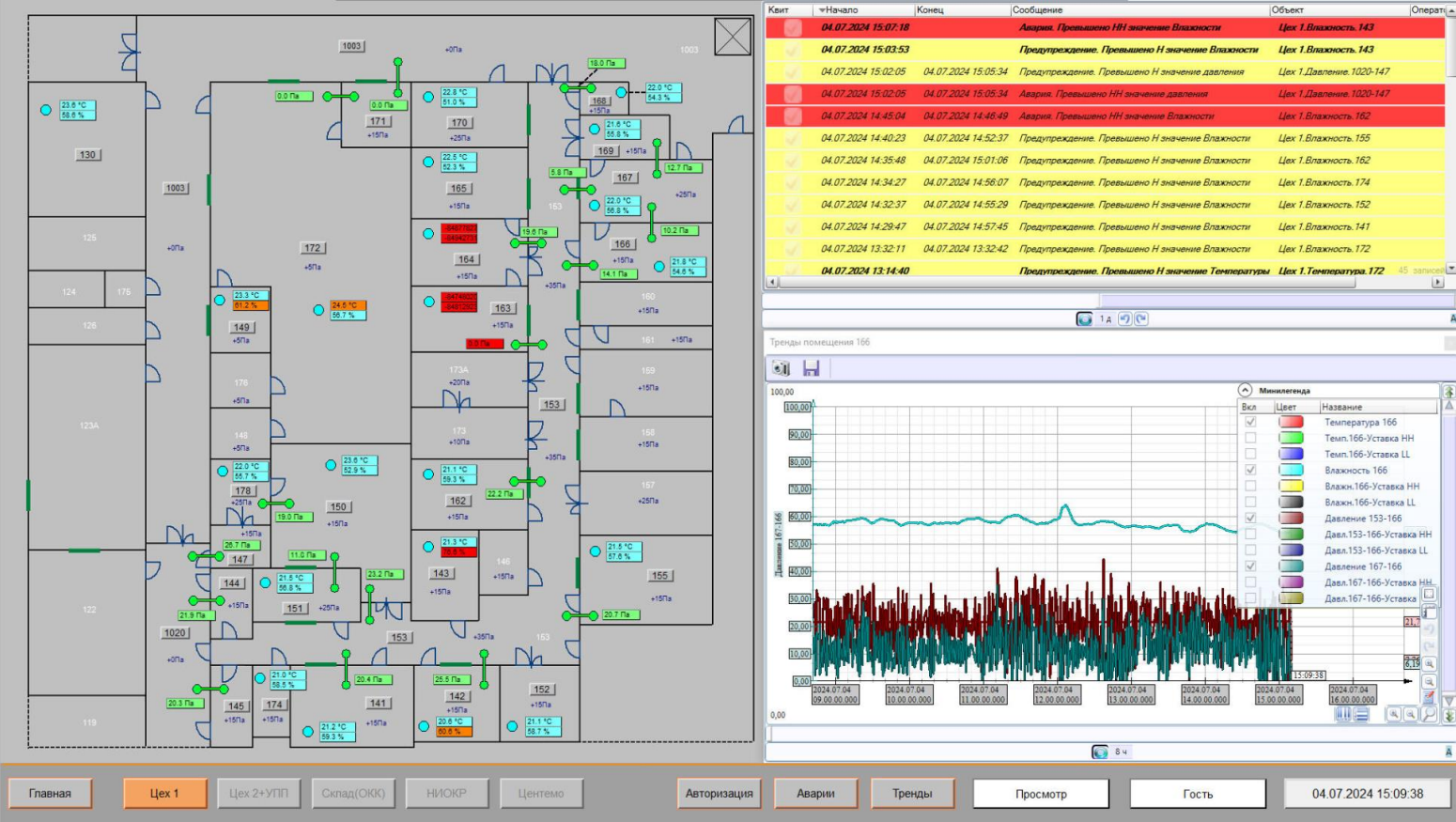

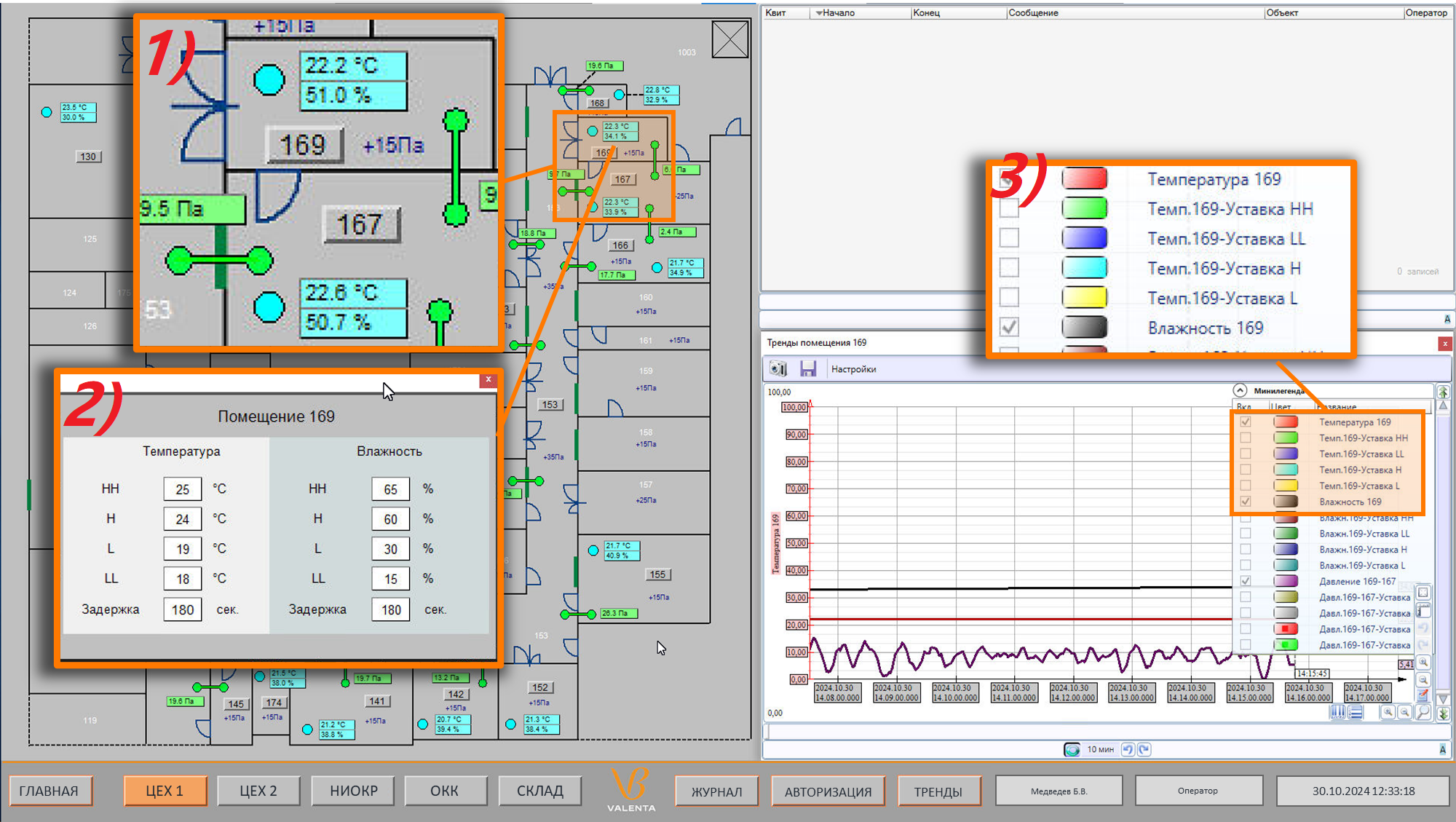

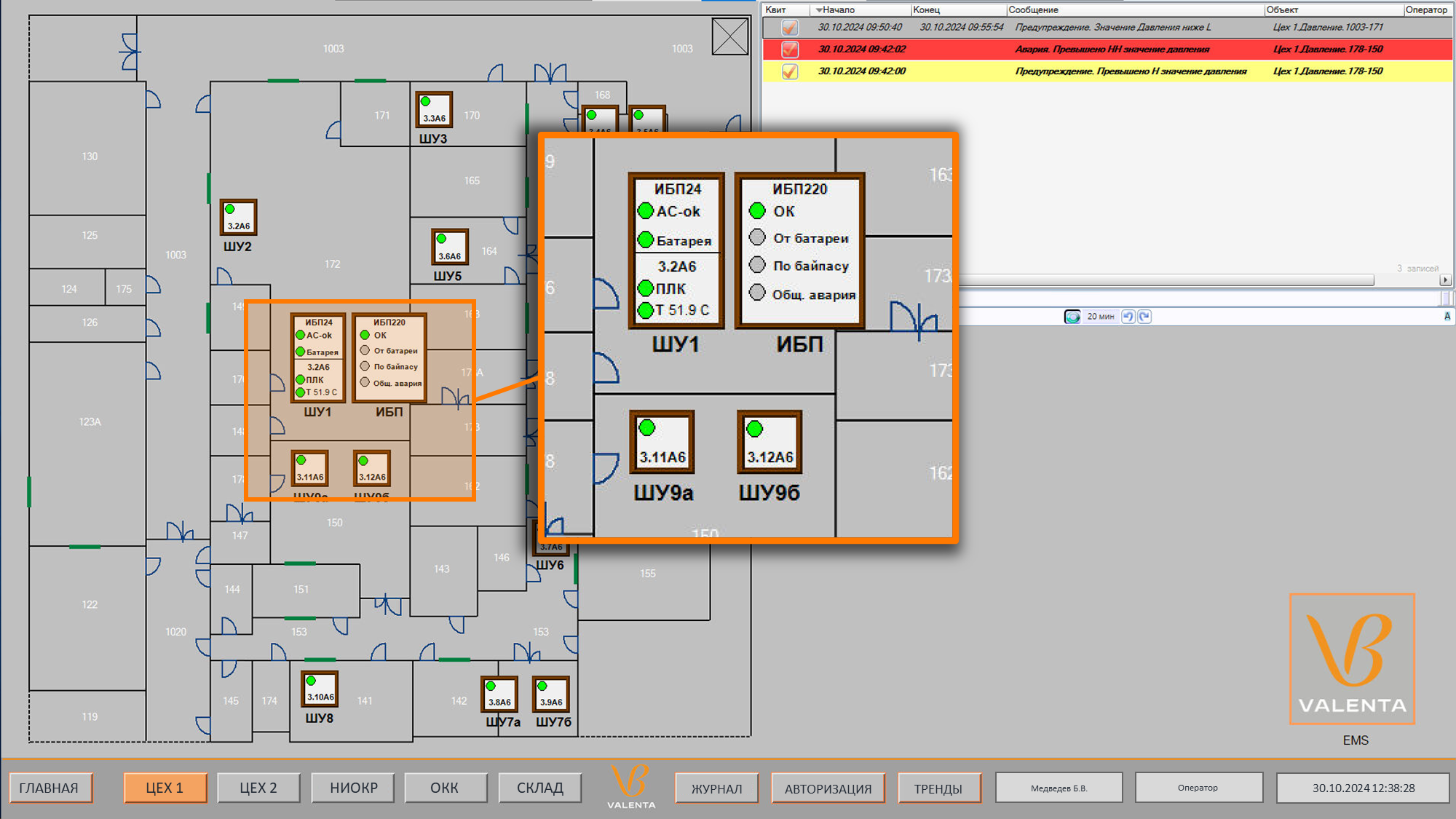

The supervisory level is managed by MasterSCADA software, which provides comprehensive data visualization and dispatching capabilities. The system presents information through numerical displays, graphical representations, and alarm notifications, enabling operators to monitor environmental conditions effectively.

MasterSCADA implementation enables the following key functionalities:

- Fully automated system operation

- Continuous 24/7 data acquisition

- Comprehensive data archiving

- Uninterrupted environmental monitoring

This multi-tier architecture ensures reliable environmental control while providing operators with real-time visibility into critical process parameters and system performance.

Within the framework of the EMS system, two servers were deployed (SCADA and database), four OWEN PLC 210 controllers, 50 control cabinets, and more than 5,000 tags. Domestic components were utilized: 69 PROMA IDM pressure sensors from NPP PROMA and 124 MICROFOR DV2 temperature and humidity sensors, covering 106 production, warehouse, and laboratory facilities.

System functions

The MasterSCADA software installed in automated workplaces provides the following functions:

Result

The implementation of the EMS system based on MasterSCADA resulted in the establishment of stable automatic monitoring of environmental parameters in cleanroom facilities, significantly enhancing the operational efficiency of the facility.

The project demonstrated:

- Full compliance with import substitution requirements

- System scalability and flexibility

- Substantial cost savings in maintenance and operation compared to similar solutions

The system has been successfully operating for over 12 months, consistently proving its reliability and cost-effectiveness in real-world conditions.