Heat&Power

December 2023 г.

System purpose

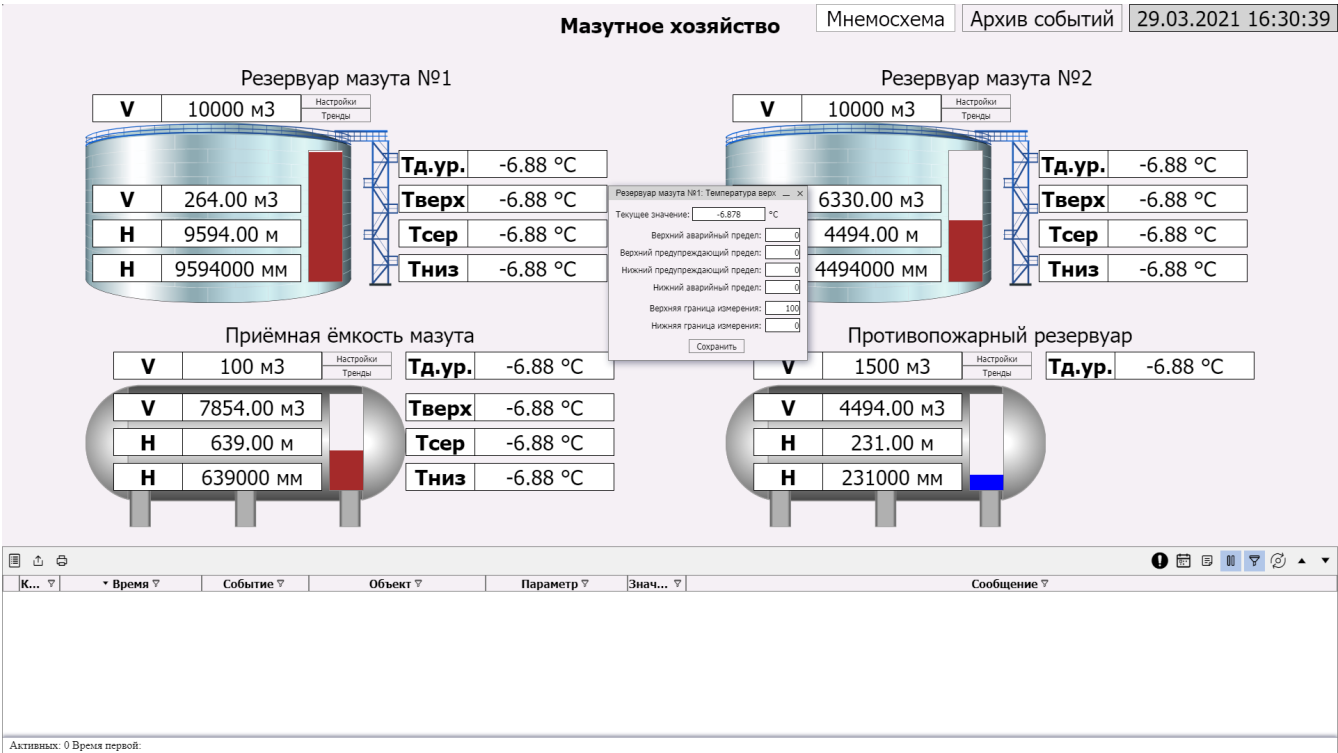

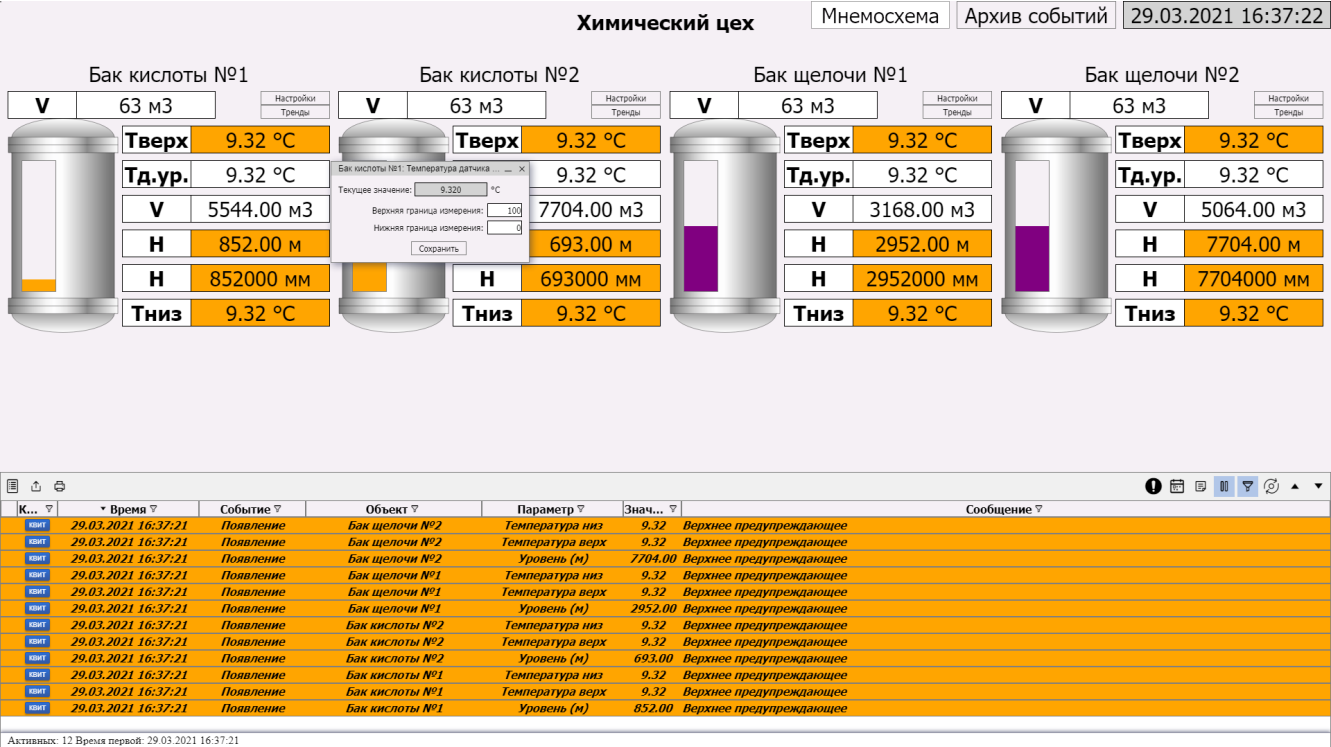

The fuel, water, and chemical reagent accounting system in the tanks of the mazut oil facility and chemical workshop of the CHP is designed for receiving, storing, and supplying the product, as well as monitoring the system's technological parameters.

- Mazut oil facility

- Chemical workshop

- Heat and power engineering complex (CHP)

Task of implementing the new system

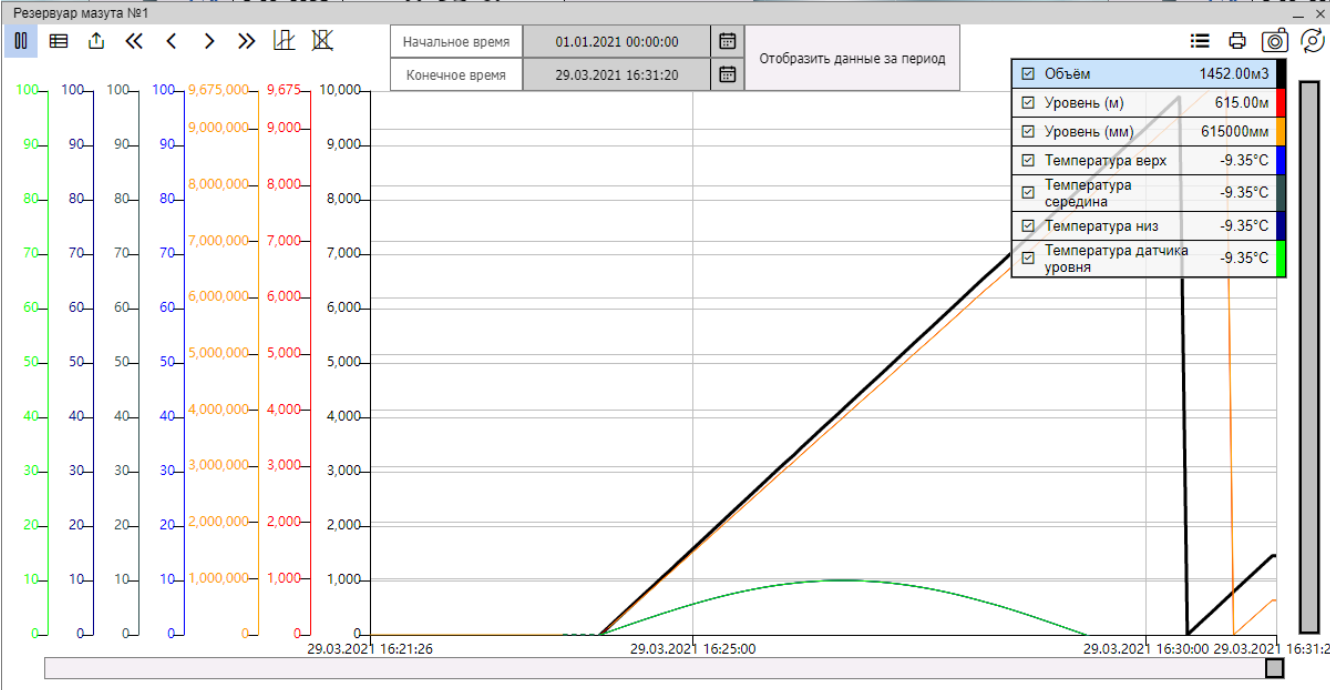

Collection, processing, storage, and provision of data on technological parameters of technical processes. Operator notification when monitored parameters exceed allowable limits. Archiving of monitored parameter values and generation of historical trends.

The implementation of the new system also included a number of other goals:

Increased management responsiveness;

Centralization of control;

Automation of processes;

Reduction of operating costs.

Solution

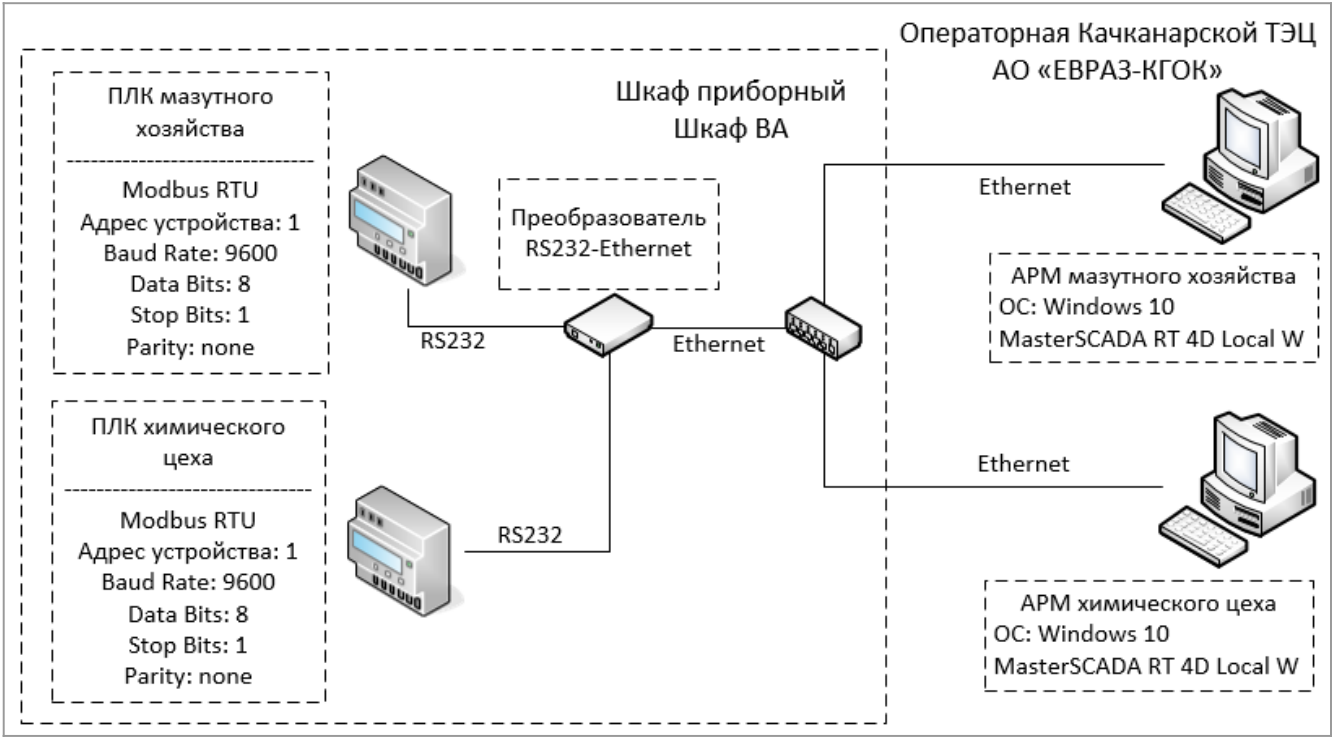

For the automation of fuel, water, and chemical reagent accounting at the Kachkanar CHP, MasterSCADA 4D 1.2 software was selected in combination with MasterOPC Universal Modbus Server. This choice was driven by a number of key advantages: support for Russian hardware platforms, architectural flexibility, and the ability to externalize part of the code into separate libraries for subsequent use. MasterSCADA 4D ensures high-speed data acquisition and full real-time control of technological processes, significantly improving management responsiveness and reducing the likelihood of emergencies.

The system was successfully integrated with the measurement and control instrumentation and PLCs installed at the operator workstations, enabling continuous monitoring and control of technological processes. Thanks to support for standard data exchange protocols such as Modbus, the solution easily adapts to the customer's infrastructure and ensures reliable integration with other systems.

System functions

The MasterSCADA software installed in automated workplaces provides the following functions:

Monitoring of technological parameters;

Timely notification of operators

Creation of a data archive;

Management of technological operations through a unified system.

Result

The fuel, water, and chemical reagent accounting system at the Kachkanar CHP provides real-time operational monitoring of parameters, which has reduced the risks of emergency situations. Improved accuracy of control and resource accounting has led to a reduction in operating costs and optimization of operator work. Process automation has increased the level of safety and efficiency of technological operations.